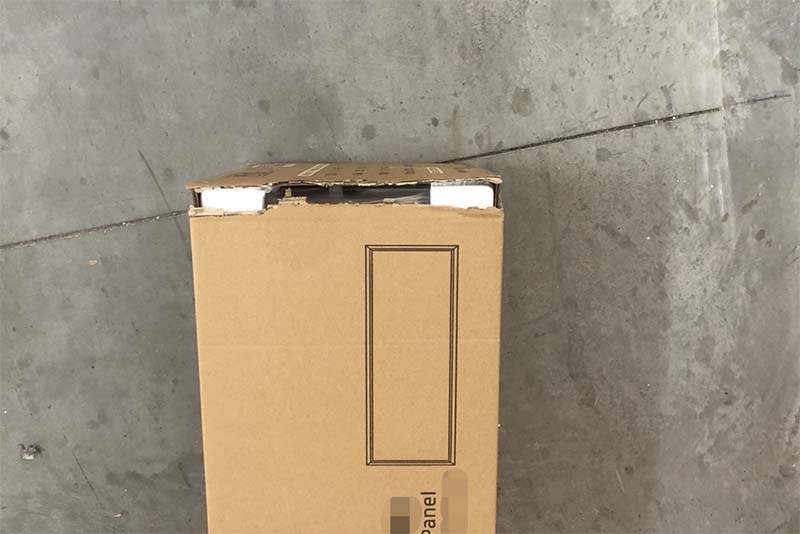

Recently, we helped a new foreign customer to do a pre-shipment inspection for their LED panel lights. During the drop testing (also called Free Fall testing), we found that some of the lights’ housings were deformed and some parts fell off.

We documented all these issues in our PSI report and sent it to the customer. And then, the customer sent this report to the panel light manufacturer.

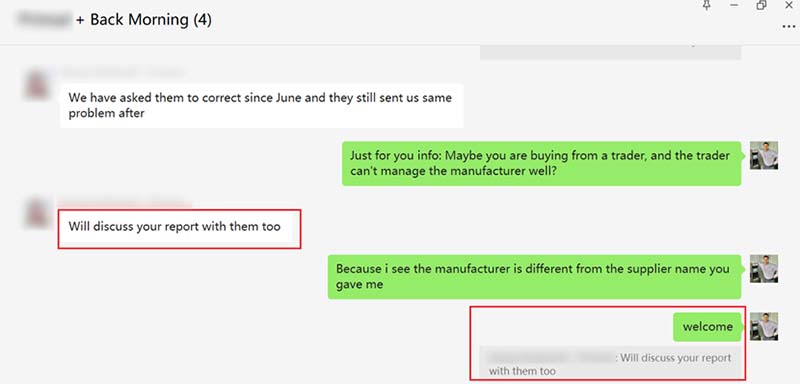

This is a new supplier. It was the first time for us to work with them. They did not know much about our inspection procedures and professionalism. Moreover, our inspection data could affect the delivery of products worth millions of RMB from the supplier.

So, almost exactly as I expected, it didn’t take long for us to receive the first question (challenge) from this manufacturer. It was forwarded via the customer: “How many times is the carton dropped in the drop test?”

Note: This question can be a trap. Our answer is very important. If our answer has obvious mistakes, the supplier may overturn our conclusions of the inspection based on this, and thus requires the customer to accept the non-conforming product.

In fact, we did the inspection at their factory in front of them, so in fact, they were well aware of our inspection process.

We answer: 6 surfaces, 3 edges, and 1 corner.

Generally speaking, if the supplier is comparatively more professional, seeing our reply above, they would know that we are operating according to the standard and would back off.

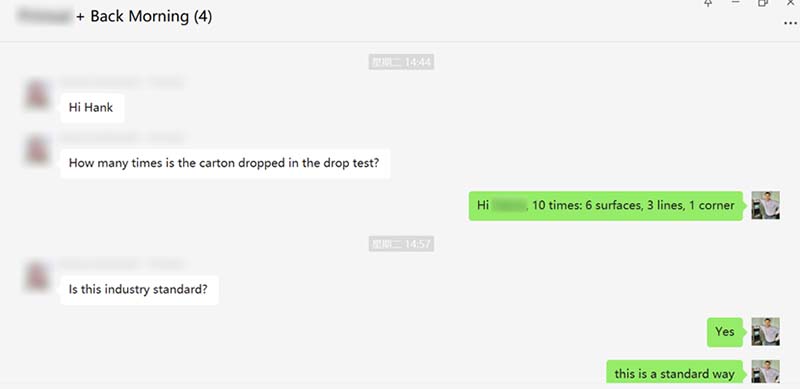

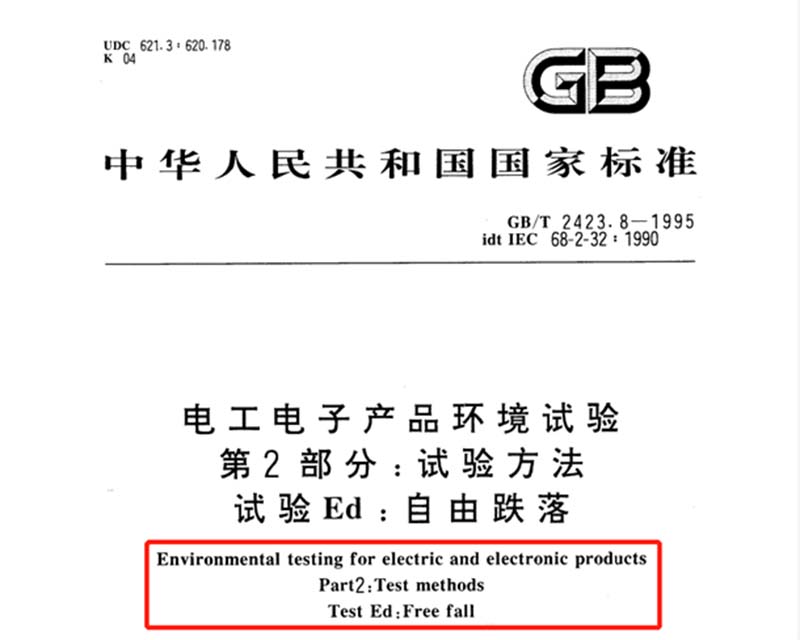

But they didn’t give up, they immediately threw a second question to us. “You perform the drop test process according to which international standard?”

I was busy with other things when the customer forwarded the question to me. And I couldn’t remember the exact standard number at that moment.

So, I went back and forth with several messages and finally confirmed the IEC standard number and told the supplier how to find it on the web.

After reading our response, the customer was very satisfied and said: Great work thanks Hank!

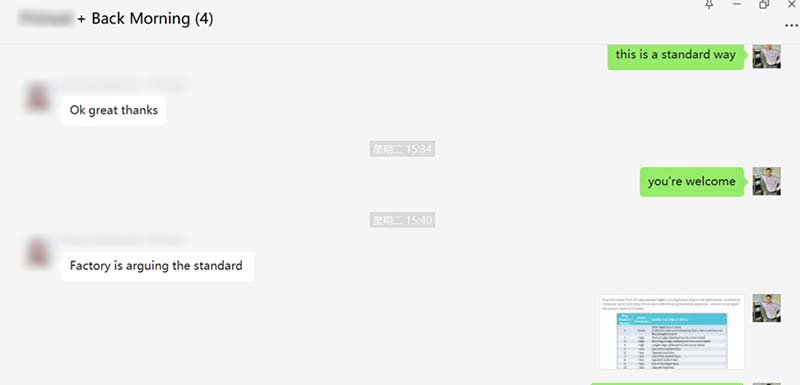

But things didn’t end easily, and the supplier didn’t admit their fault easily. After all, it was for panel lights worth millions of RMB. They had to fight for any chance.

So, it didn’t take long for the supplier to throw a third question to us through the customer. “Is this standard suitable for LED BACKLIT PANEL?”

We answered: “Of course. LED backlit panels are also an electronic product”.

A fourth question:

“We re-made the product. So the glue is not dry. You can check with inspector he should know the main reason of fall off is glue not dry but not drop test.”

Actually, when I saw the 4th question, I believed the supplier was being a bummer. So, I replied to the client like this.

“Factory has the responsibility to ensure all the goods are well prepared before we inspection. If they say something like this, we can’t verify, we can only ignore it”.

The customer replied: Agree totally and they confirmed the time.

The supplier confirmed first the time of inspection with the customer, so we went according to the time confirmed by the supplier, so the customer completely understood us.

This story, for the time being, it comes to an end here. And the customer did not come back to us later. You may not have thought about it – to do a quality inspection, we need to answer so many questions. Right?

However, through answering these questions, we have more communication and understanding with our customers. There are more opportunities to build trust and reflect our value. I am happy to do these answers.

Last but not least, BackMorning is a third-party quality inspection company focusing on the LED lighting industry.

Drop us a line if there is anything we can help you.

Hank Wang

Six Sigma Green Belt. Third-party quality inspector focusing on LED lighting. 15 Years' experience of supplier quality management.