How can you buy good LED lights from China, and minimize the quality risk?

Generally speaking, you will need to pay attention to 2 things.

Let me explain one by one.

1. Choose an LED light manufacturer that focuses on quality

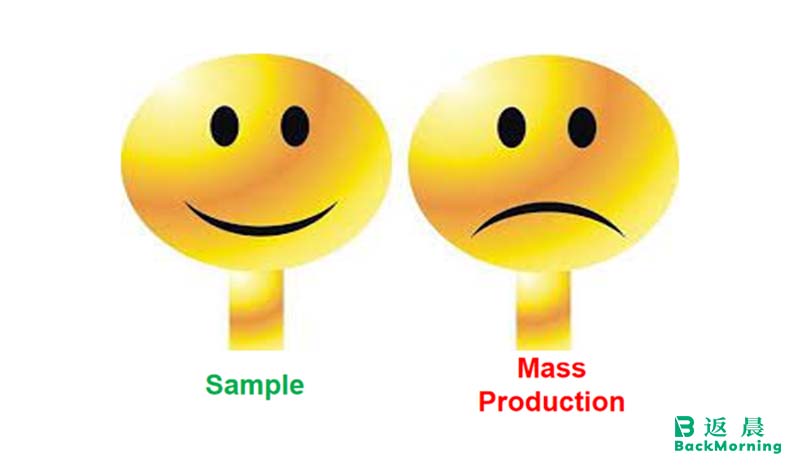

Remember, even a small workshop can make relatively high-quality samples.

However, it’s absolute that only quality manufacturers can assure quality in mass production.

And their quality is stable and reliable in the long run.

In the LED lighting industry, quality manufacturers can make LED lights with a very low failure rate in 3 years, and 5 years in China.

It’s also possible to keep it very low within even 7 to 10 years.

I would also want to share a story here.

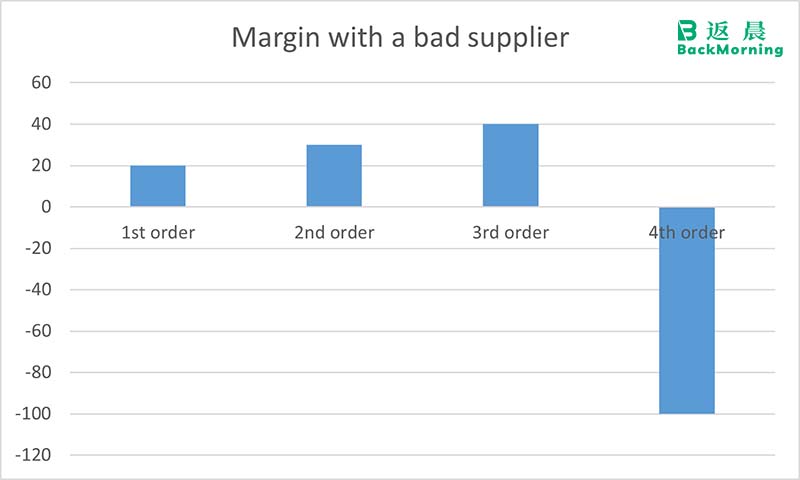

If you work with an unreliable manufacturer, you may make profits with the first order.

And make profits with the second batch of LED lights.

Even the third batch continues to make profits.

However, it’s possible that the 4th batch of lights may make you lose more than the profits you’ve made with previous batches.

Therefore, choosing a quality manufacturer is like avoiding gambling.

And on the contrary, this strategy helps you make low-risk and continuous profits.

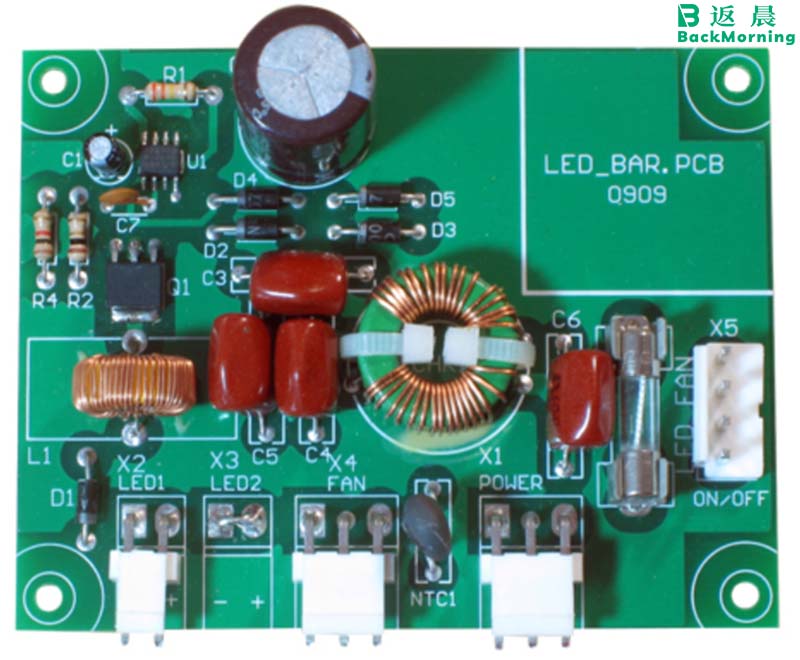

2. Make sure to do professional tests with LED light samples and mass production.

This is a critical step.

Even high-quality manufacturers are sure to make mistakes.

Why?

If an LED light is the manufacturer’s new product, the production is not yet optimized.

The probability of error will certainly be high.

If it is an old product, the following factors may happen and will also lead to quality problems:

1). The workers on the assembly line have changed.

For example, it is now summer.

Some LED light manufacturers are recruiting cheap summer workers (students).

They do not provide strict training to these new workers.

2). The machine on the production line has issues.

Or has just been replaced by a new machine

And workers are not yet familiar with the new machine.

- For example, in the lighting industry nowadays, there are more and more automatic machines.

They include automatic dispensing machines, automatic screwing machines, automatic wire soldering machines, and automatic packaging machines.

They are helpful for improving the overall production efficiency.

And also good for long-term product quality.

But during the initial stage, there will be a period of instability.

3). The type of raw material has changed, or the supplier of raw material has changed.

This includes electronic components, screws, glues, and so on.

- For example, many outdoor LED lights will use waterproof glue.

- However, waterproof glues of different manufacturers will have different adhesion, solidification time, etc.

If you change the glue, but the corresponding gluing process and the sequence remain unchanged, there can lead to batch quality problems.

4). Simplify some production procedures during the time rushing for deliveries.

Especially, before the Chinese Lunar New Year and the National Day holidays.

The manufacturers will try their best to produce so they can deliver before the holiday.

But the capacity is definitely not enough according to the normal production processes.

So, preheating is ignored for which should have been preheated.

Aging is ignored which should have been aged.

They skip many time-consuming process steps.

Leaving more hidden quality problems behind.

5). The weather changes.

For example, it has been dry before, but it has been raining recently and it’s wet everywhere.

In this case, the quality of electronic raw materials for LED lights are affected by the humidity of the air.

Moisture will also be absorbed into the interior of the outdoor lights and causes water mist and so on.

Well, so many things to be careful about buying LED lights!

Hank Wang

Six Sigma Green Belt. Third-party quality inspector focusing on LED lighting. 15 Years' experience of supplier quality management.

Related posts:

UGR Test according to CIE 190:2010 for a French Customer

UGR Test according to CIE 190:2010 for a French Customer

Expected Characteristics for Quality Inspection Companies in China

Expected Characteristics for Quality Inspection Companies in China

9 Reasons Why the Quality of Products Made in China Isn’t Poor

9 Reasons Why the Quality of Products Made in China Isn’t Poor

7 Reasons to Consider Buying from Manufacturers in China

7 Reasons to Consider Buying from Manufacturers in China

Pre-shipment Quality Inspection for 1,500W LED Stadium Lights

Pre-shipment Quality Inspection for 1,500W LED Stadium Lights

13 Steps to Inspect LED High Bay Lights before Shipment

13 Steps to Inspect LED High Bay Lights before Shipment