BackMorning – Quality Inspection Company

Make quality inspection visible and reliable for LED lights

Hi, I’m Hank Wang, the founder of BackMorning.

A service provider of Supplier Quality Management in the LED lighting industry.

Typically, SQM companies work for various industries and products.

Differently, BackMorning focuses on the LED lighting industry.

Therefore, we are a better choice if you wish to buy better LED lights and work with better manufacturers in China.

Particularly, we have additional practices to assure our service quality.

The quality of our service is as important as the quality of your products.

So, we manage our inspection processes with modern information technology.

- That is, each of our inspectors will carry a wireless webcam for an inspection task.

- This makes the process visible and trackable and helps us make it better and better.

- None of other third-party inspecting companies do this yet.

Our headquarter is in Shenzhen, Guangdong province.

And we have branches and people in Zhongshan and Ningbo.

These cities are where most LED lighting manufacturers are located.

This helps you save time, money, and resources.

With obvious potential in the field, we’ve been working with some of the top 10 lighting brands in the world

Moreover, we’re also working with some of the finest companies in specific countries and regions.

You may wonder how we can achieve this.

I want to tell you a story from the beginning of BackMorning.

That’s it.

No big deal.

Just a story from my life.

1. The Beginning of BackMorning as a Third Party Inspecting Company

2014, I was working in a multinational company in Shandong province.

My position was for quality inspection and supply chain management.

I face quality management all day long – Advanced Product Quality Planning, 8D, Lean Production etc.

And then, I wish to try something more passionate and challenging.

Then I quit and came to Guangdong for the export business of LED lights.

Luckily or unluckily, I got several good customers within a year.

But the good times did not last long.

- There were many after-sales problems due to quality.

- Those customers did not come back for new orders.

- And the money did not end up in my pocket.

All the efforts went down the drain because of quality issues.

This story is not a small blow to me, but a shock to me.

It changed my mind completely.

But at this time I suddenly realized that product quality is the foundation of everything.

Nobody wants to buy something that doesn’t work.

Then, an idea popped out of my mind.

Why not go back to quality management?

I repositioned my company to provide supplier quality management services.

And I changed my company name to BackMorning.

Morning can also mean “origin”.

The origin of my career was quality management.

So, I go back to what I started doing and make it a lifetime career.

This would not have happened if I hadn’t failed because of quality issues.

It was awful tasting medicine, but the patient needed it.

Sometimes life hits you in the head with a brick.

But don’t lose faith.

I’m convinced that the thing that has kept me going was that I loved what I did.

2. The Focus of BackMorning – Quality of LED Lights

Like I said.

The entire focus of BackMorning is the quality of LED lighting since the beginning.

- So, we spend all our efforts on how to ensure LED lights quality better.

- That helps us learn and gain experience as time goes by.

- Particularly, it’s been our honor to work with some of the global lighting brands.

- That makes a dramatic difference between us and other quality service providers.

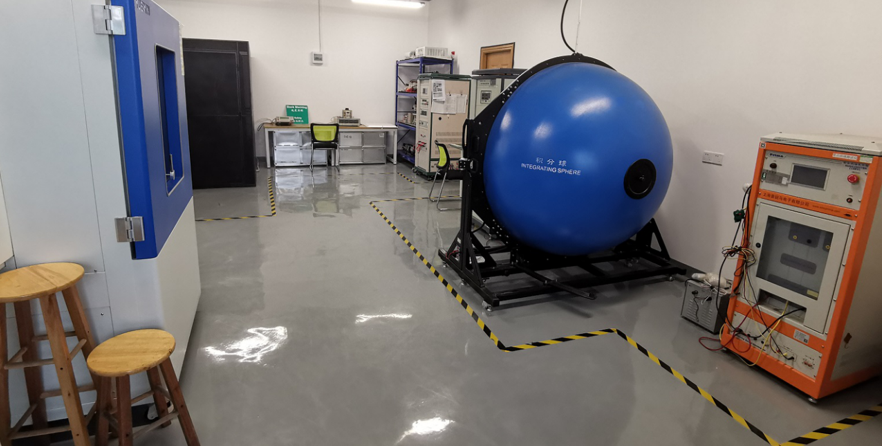

Needless to say, you will need test instruments to obtain different data from a product.

Then, you can tell whether the quality is good or not.

Therefore, we have invested in a complete set of testing instruments for LED lighting.

The tests that we can do for you include

- Safety, photoelectric, thermal management, surge protection, waterproofing, and working temperatures.

And we have invested in training our inspectors.

They have received comprehensive training.

- The types of training include ethics training, confidentiality training, and operational training.

- The operational training includes lighting product safety, optical testing, process inspection, etc.

- Moreover, they are also trained and certified by our customer, who is one of the top 3 brands in the world.

It can be easy to buy all the necessary testing instruments.

It is only a matter of money.

But, it’s very challenging to find the right people.

- It takes time to train them and help them gain knowledge and experience.

- There are lots of efforts before they can do something.

3. BackMorning is a Good Choice to Work with for Better Quality

It’d be a good choice to work with BackMorning.

You don’t have to invest in a lab of your own for your LED lights.

We can help you with various targets.

- Simplify your supplier quality management by reducing manpower, equipment, and training

- Save time on quality inspection work and reduce travel costs

- Reduce the number of failed products

- Ensure good quality for lighting projects to maintain a good reputation in the market

- Quickly find problems in product quality to solve problems timely and effectively

BackMorning can take care of the entire process for you.

- Begin from product and supplier selection and qualification

- To the purchase of raw materials

- To product manufacturing process

- And pre-shipping inspection – the last step of delivering good LED lights to you

Manufacturer qualification:

- Help buyers choose the right products and manufacturers at the initial stage of the projects

- Common practices include sample testing and supplier audit

- So, we can minimize the risk of bad quality.

In the process of cooperation:

- Pre-Shipment Inspection to stop quality problems before shipment and greatly reduce quality problems in the end market.

Continuous improvement:

- Help brand owners and manufacturers make their products better and better in the long run

- Including production audit, find problems in the production process management of lighting industry factories

Sounds good for you?

4. Types of Customers that Work with BackMorning

You may wonder whether our service is for you.

Well, the customers that BackMorning serves are various.

Some are household names in the world.

- Some of the top 10 global lighting brands

- They have wide product lines for indoor and outdoor applications.

- Illumination, ambiance and accent lighting, media and facade lighting etc.

Some are reputable lighting solution providers for specific countries and regions.

- Swissled: European lighting solution provider for excellent lighting projects

- Lekise: Famous lighting brand in Southeast Asia

And also, some other customers who excel in their niche markets.

- Maxlite, Spectrumled, Siteco, Enarlux, Lumiverso, etc.

It’s really not as easy as it seems to buy good LED lights that will last long.

Needless to say, you’ve seen such issues in this industry.

- Incorrect or inaccurate claims of performance in marketing materials

- The real safety, optical, spectrum, IP performance of many LED lights are far from they claim.

High inspection costs, resulting in the insufficient inspection of product performance:

Inspection is an important means of ensuring quality.

But it requires frequency, intensity, and professionalism.

But due to the cost, this inspection is often not performed in place and does not ensure a reasonable frequency of inspection.

Quality comes from good process management.

Product quality comes from an effective quality management process.

It starts from the development stage of market research, product design, testing, verification.

Also includes raw material management, production process management, staff training, process inspection, pre-shipping inspection, etc.

The quality of a product is not just determined by the final inspection.

Especially, picking random samples is far away from satisfaction.

You must build quality through a consistent collaboration of the whole process.

5. Brief Customer Stories

My first story is about a European purchaser who imported panel lights from China.

- Unfortunately, they had an issue and the purchaser’s inspector found it.

- The actual luminous flux efficiency of the panel lights was 30% lower than the data claimed by the supplier.

- And they realized this after the products arrived at the purchaser’s warehouse.

After investigation, this was because:

- The supplier used an integrating sphere to measure the luminous flux.

- And did not correct the parameters of the instrument correctly.

- This caused a great loss to the purchaser.

Later, the purchaser contacted BackMorning for better supplier quality management.

- BackMorning was clear about the characteristics of different testing instruments.

- We required all panel lights to have their luminous fluxes tested by a Goniophotometer.

- And it prevents all similar quality problems before shipment.

My second customer story is about a US buyer.

They have been purchasing lights from China for a long time.

- May 2021, they notified their supplier not to use plastic bags to pack the lights’ bodies due to an environmental protection regulation.

- The supplier forgot this notification during the packaging process.

- Fortunately, the BackMorning inspector identified this problem during the pre-shipment inspection.

- And the supplier corrected this packaging mistake and avoid loss.

My 3rd story is about a customer in South America.

They sold their floodlights to the market, and there were many problems due to water leakage.

Then they talked with BackMorning.

And we checked the supplier’s production process thoroughly and conducted intense waterproof tests.

Finally, we helped them identify the cause and found a solution to make improvements.

You see.

These customers achieve their targets after working with us.

If you have issues with buying quality LED lights and working with reliable manufacturers in China, just drop us a line.

I look forward to hearing from you sometime soon!

Hank Wang

CEO & Founder of BackMorning