I had a very meaningful communication with Mr.Fabrice recently. Regarding the quality of Made in China, how to find truly high-quality suppliers and how to work with Chinese suppliers. I have compiled this content in the hope that it will be helpful to buyers who need to find suppliers and products in China.

Fabrice, a French engineer with more than 16 years of experience running factories in China, shares his insight on working with Chinese suppliers. His journey began in Dongguan, a major industrial city near Shenzhen, where he started his first factory in 2007.

Table of Contents

1. An Insider Perspective : Work with Chinese Suppliers

1.1 Understanding “Made in China”

When discussing their perception of made in China’s quality, Mr. Fabrice encountered a prevalent phenomenon abroad: If some products are faulty, pepole often attributed solely to their origin as “Made in China.” As someone who has been residing in China for an extended period for Fabrice, who has been residing in China for a long time, it makes him unhappy.

Fabrice believes that the quality of “Made in China” varies dramatically. From low-end toys to complex nuclear power plants, China’s industry has it all. The issue lies not in the quality of Chinese products, but the perception of it. Often, when a product breaks, it’s mistakenly attributed to its Chinese origin. Actually, you can find products made in China in various grades.

1.2 Evaluating Working with Chinese Suppliers

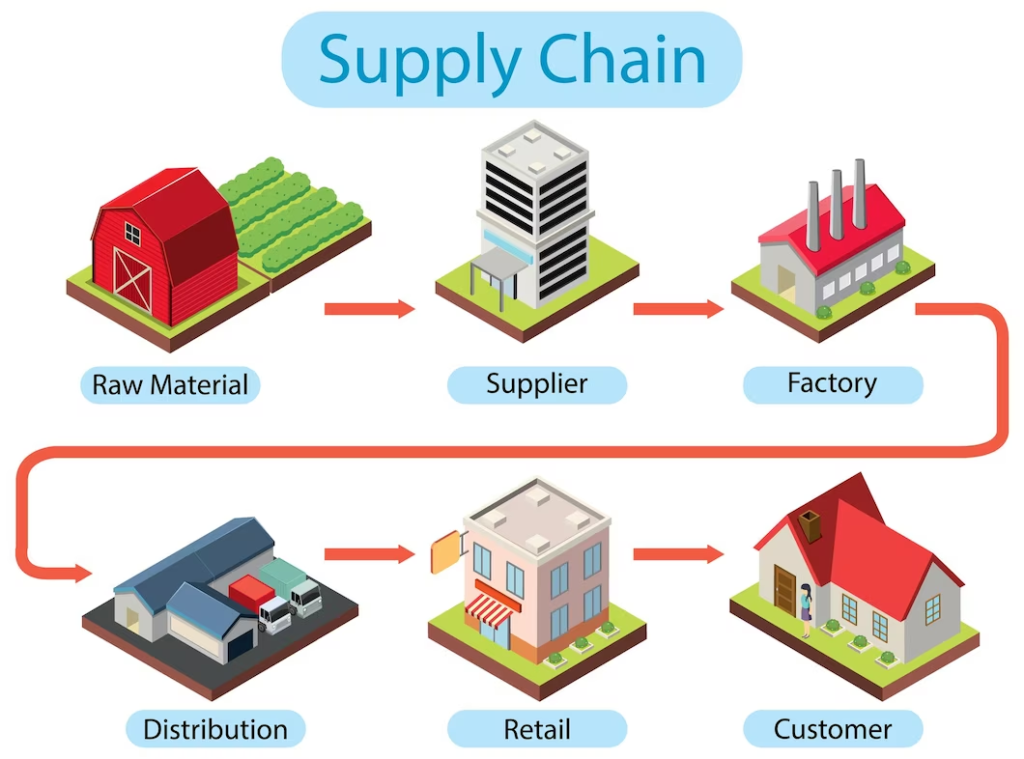

In Fabrice’s experience, working with Chinese suppliers is akin to working with suppliers anywhere else in the world. There are good and bad players in every market. For instance, Fabrice had to bring certain operations in-house due to the lack of reliable suppliers. And he found local Chinese companies that offered good quality molding, stamping, and PCBA.

We deem that such inherent thinking is unacceptable as it does not encompass the entirety of Chinese manufacturing. In his opinion, China industry we can find everything. The quality of products manufactured by Chinese factories varies, and it highlights the crucial role of quality management in product development. We hope that all manufacturers do not forget this important aspect.

1.3 Finding suppliers online is risky

A common trap when looking for suppliers online is the disparity between their online presence and their actual capability, says Fabrice. While some suppliers may have excellent and professional-looking websites, the reality can be a different story. It’s crucial to visit the factory, examine their processes, and ensure that they are in control of their operations.

1.4 Defining a Good Factory

According to Fabrice, a good factory isn’t defined by certifications like ISO 9001. Instead, he believes in understanding a supplier’s purchase process, evaluating the quality of the products they receive from their suppliers, and checking for any bad records. He also emphasizes the importance of a factory’s production process, their understanding of it, and their ability to execute it. Interestingly, he also includes the condition of the factory’s toilets as an indication of their attention to detail and financial stability.

1.5 Encouraging Suppliers to Improve

Fabrice believes in giving suppliers the opportunity to improve. He sets clear expectations and works with them to achieve these goals. For him, the commitment of the factory’s management is crucial. If the boss commits to improvements, they will usually be realized. He concludes with a hopeful message for suppliers who might not be up to standard, that with time, commitment, and step-by-step improvements, they can reach their goals.

In conclusion, working with Chinese suppliers is a nuanced process that requires an in-depth understanding of the manufacturing landscape, a hands-on approach, and a willingness to help suppliers improve. Fabrice’s insights provide valuable guidance for companies looking to navigate this process successfully.

As a third-party quality inspection company, we are equipped to safeguard the quality of your LED Lighting products. Our services encompass professional quality inspections, sample testing, and assessments of factory capabilities to provide you with peace of mind regarding product excellence.

Email: [email protected]

WeChat: LNY0539

Whatsapp: +86 18616827523

Web: www.backmorning.com

Supply Chain Management Professor.

Quality Inspector in Lighting Field and Steel Structure Field.

Certified Welding Inspector by American Welding Society.

15 Years' experience of supplier quality management.

Six Sigma Green Belt.

Now I am going to do my breakfast, once having my breakfast coming again to read more news.

You are welcome. Welcome to contact us via Email [email protected] if you have any questions.