Recently, as a third-party quality inspector, I recommended an LED light factory to a pretty good buyer,who is very strict at product quality. Many friends are curious why I recommend this factory. Is it because the factory is big? Is it because the factory gave me a bonus? Is it because their prices are low?

These are all very normal and natural questions, and I can fully understand them. However, these questions contain some misunderstandings, so I need to explain.

I want to express the following points:

- What is a shoddy workshop? Some people think that small factories are shoddy workshops. This view is incorrect. Small factories with good quality management are not shoddy workshops, and large factories without quality management are equivalent to shoddy workshops. So when we recommend factories to buyers, we based on the perspective of quality, not based on the scale of the factory;

- For some standard products, we must focus on the scale of the factory when screening and recommending factories. For example, normal light bulbs, tubes, ceiling lights, panel lights, floodlights, etc., in today’s mature LED industry, if a factory does not have a certain scale, it will be difficult to have the cost advantage of raw materials and the advantage of automated production, and thus difficult to have price competitiveness; for customized products and special products, large factories can’t do them and don’t want to do them, so it’s more suitable for small factories to do them, such as lights with special colors, shapes, wavelengths, and functional requirements.

- What is a reliable quality factory? According to our factory evaluation process, we need an evaluation report of dozens of pages to confirm whether the factory is reliable. So, in detail, I won’t say it step by step, I’ll show you a picture, and you’ll know why I recommend this factory.

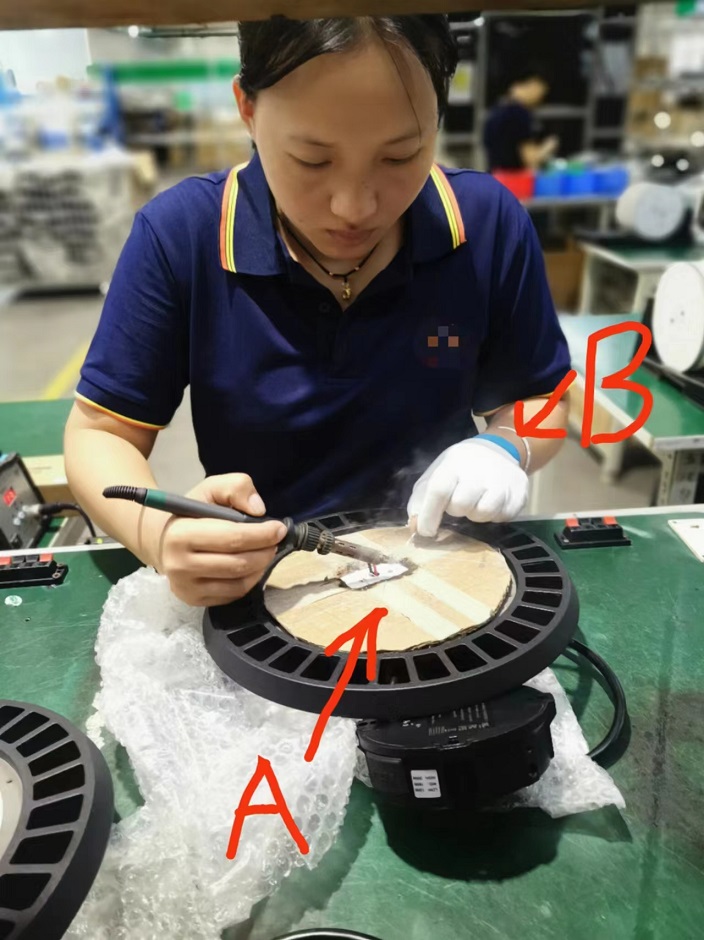

- Let’s take a look at this picture. It’s the factory production line workers soldering the wires to the light board. At least several details in it prove that this factory meets our requirements:

- Work clothes: The workers wear the factory’s work clothes, and the factory’s name is on the clothes. The clothes are not brand new, indicating that they are not temporarily prepared and not specifically for us to see. You should know that soldering is a key position and requires experienced old workers to operate. Wearing work clothes means a higher chance of being an old worker.

- Protection for the lamp beads during soldering. She is actually soldering an LED High-Bay Light. She covered the lamp beads with a piece of cardboard and then soldered it. As you can see, the lamp was originally like this. To protect the lamp beads easily, she covered it with a piece of kraft paper(A in below picture), leaving only the solder pad exposed. This way, during soldering, the splashing tin beads won’t damage the lamp beads.

- There is a blue bracelet on her hand(B in below picture). What is this for? You should know that our body, due to the friction of clothes, hair, etc., will generate some static electricity. The voltage of this static electricity is very, very high, reaching thousands or even tens of thousands of volts. Therefore, if we touch some electronic components, such as LED lamp beads and driver power components, without protection, it may cause some damage and injury. These injuries have a certain degree of concealment and may only manifest after half a year or 2-3 years of use. To avoid quality problems caused by such static electricity, some measures are needed to release static electricity, and the blue bracelet on the employee’s wrist is an anti-static wrist strap.

In fact, whether it’s work clothes, cardboard, or anti-static wristbands, the material costs are very low. However, to get this system up and running, you need to think about it and need the factory owner and management to pay attention to these cost-increasing trivial matters. And to get this system running 100% perfectly, without a single mistake, it takes more than just attention, it takes a very comprehensive quality management system.

And as a third-party quality inspector, when I investigate and recommend LED light factories, the above details are the key factors in deciding whether to recommend them or not.

We can help you in China to avoid 95% of the products quality issues, get high quality LED Lighting, Solar and Electric products, by providing you supply chain management service: Inspection, Testing & Sourcing.

Email: [email protected]

Wechat: LNY0539

Whatsapp: +86 18616827523