Showing Their Quality Management process

Many buyers ask me to introduce good quality LED lighting manufacturers.

But as a quality inspector, it’s not my style to introduce suppliers based on:

How cheap the prices they can offer.

How big the size of the factory is.

Or how good relationship between me and the boss.

When I introduce the suppliers, I have the most important point is QUALITY.

I only introduce the suppliers whose product quality is OK.

They can pass our quality testing for each safety, lumen, IP rating, and heat transfer.

And they have a trusted quality management process.

Because quality comes from the process.

Now I am going to introduce a good quality lighting manufacturer – Shenzhen AOK LED Light.

They focus on high quality, and high power outdoor LED lights.

I will show you how we can verify it by a quick factory audit in 6 steps.

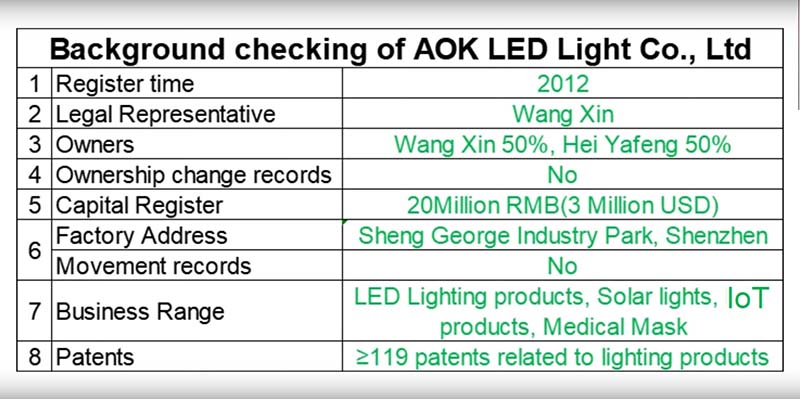

Step 1. Background research

We can collect information from the National Enterprise Credit Information Publicity System.

This table shows important background information we found about AOK LED Light.

1). Registration time

The registration time of AOK was 2012.

- This is earlier than 80% of lighting manufacturers in China.

This is good.

In China, we can say it’s a long-time factory.

Because China joined the World Trade Organization in 2001.

Many companies started after that time year by year.

And the lighting industry began popular around 2010.

2). Legal representative

And we can see the legal representative is Wangxin.

Who is a legal representative?

- It’s the person with the greatest legal responsibility within this company.

- It may not be the biggest owner of the company or the company’s actual beneficiary.

It’s preferable to choose a supplier whose legal representative and owner are the same person.

It’s from the point of view of an auditor.

3). Owner

Wangxin and Hei Yafeng respectively own 50% of the company’s shares.

So, combining points 2 and 3, we can find Wangxin is the legal representative and the owner.

That’s good.

4). Ownership change record

It’s good to see they have no ownership change record.

- This means the top management team is very stable.

5). Registered capital

AOK has a registered capital of 20 million RMB, which is around 3 million US dollars.

- This number is also bigger than 80% of lighting manufacturers in China.

- I have to remind you that registered capital is the measure of a company’s legal liability.

6). Address and relocation records

This factory is in Saint George Industrial Park.

It has not changed in the past 10 years.

This is also stable.

7). Business range

The business range approved by the government includes LED lighting products, solar lights, and LOT products.

So, we can get very important information.

They focus on the lighting industry.

8). Patents

We find they have at least 119 patients and all related to LED lights.

And all of them are related to LED lighting – wall lights, and solar lights.

- 9 of their patents in 2022

- 36 of their patents in 2021

- 25 of their patents in 2020

This means they continued designing new lighting products in the past 3 years.

I think everybody can understand why it’s can pass the background check

Step 2. Onsite Audit

Next, I go to the factory and do the onsite audit.

After arriving in front of their factory, I can see their logo on the building.

I use the map app on my phone to verify the actual address.

I can find the St. George Industry Park.

It’s the same as the official registration information.

Then I go inside and have a meeting with them.

Step 3. Visit the showroom

They have many certificates and medals on the left part of their showroom.

And the right part is for demonstrating their products.

- Most of the products are streetlights.

- And some stadium lights with big sizes.

Meanwhile, they have another showroom for the high bay lights

Because they make lights for some applications like the warehouses.

Normally, if I visit a showroom, I’d like to feel the product, and to feel the weight.

Because for LED lighting, the lower temperature the light is, the longer lifespan it has.

So, to ensure a suitable temperature, they have to ensure enough cooling to enhance the heat transfer.

So, I prefer a strong housing, which means a heavy light.

I have a quick visit to their showroom.

And check some points of the products there, such as the weight.

- I can see their outdoor lighting products include stadium lights, streetlights, and high bay lights.

- The results are the same as my independent background check.

- Their showrooms show the same information they give to me.

Step 4. Visit the laboratory

Next, I visit their laboratory, which is beside their production lines.

- I see their integrating sphere, which is for the parameters like CCT, Ra, and SDCM.

- These are the important parameters for LED lighting.

As an auditor, I can’t just check if they have these instruments or not.

Also, have to ensure they have trustable accuracy.

So, I check if they have some third-party calibration.

- It turns out each instrument has a third-party calibration label.

- We have to do this calibration every year.

Good to see AOK’s instruments are still within the valid time.

Next, I check if they have any working instructions.

And they also have various reports on the wall, like the one for CCT standards.

In the laboratory, instruments require suitable humidity and temperature to ensure their accuracy.

And I see an instrument for IP testing.

- For outdoor lights, IP testing is very important.

- Because IP failure is one of the top three failure reasons for LED lights.

And they have another IP testing machine for another standard.

And attached with testing records.

Besides, they also have salt testing and vibration testing machines.

The lights will be put into cartoons and loaded into containers.

They will be on the road for days, even several months on different roads.

This kind of testing is important to ensure good protection for the products.

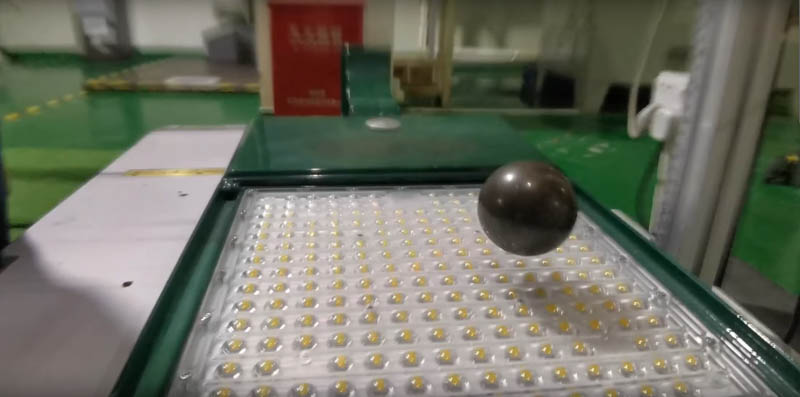

They have a drop testing device in the lab.

And I ask their technician to demonstrate according to the standard.

Next, I see they are doing load testing for streetlights.

And I see 2 types of load – 60 kgs and 40 kgs.

They have machines for high-temperature testing and low-temperature testing.

It can also simulate different humidity.

They set the temperature to -30°C.

And put a light inside to see if this light works well.

This test will take a very long time after the light is turned on inside.

Next, I check their darkroom.

- It is for the IES testing to check the light distribution of streetlights and stadium lights.

- And you will get an IES file or LDT file by this testing.

We can see this room is very dark, and the walls are painted with dark materials.

And inside I also feel very cool, because they install an air conditioner inside.

The purpose is to control the temperature and humidity of the dark room.

This is to ensure the accuracy of this testing result.

The darkroom is OK.

We always check this during our production audit.

Step 5. Visit the production lines

I have some difficulty taking some video shots with their production lines.

Because products on the lines are their customer’s designs, with the customer’s logo.

Why I’m telling you this?

Because we have to respect the intelligent properties of the buyers.

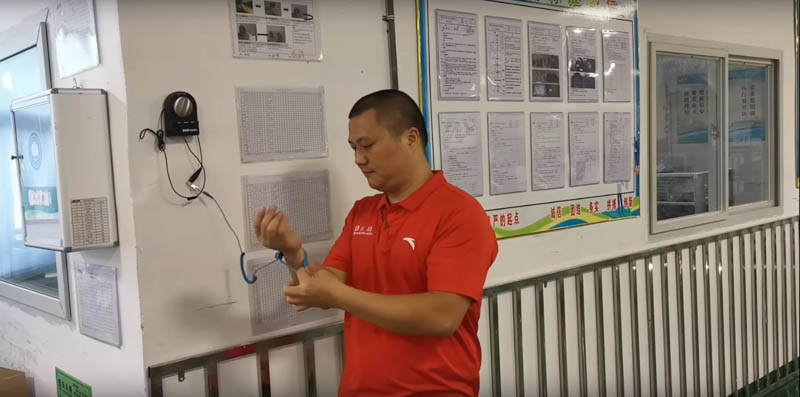

- They have an area for checking the Electro-Static Discharge.

- And they attach a work instruction on the wall.

- Meanwhile, there is a small device to check if the workers’ ESD control ring is working or not.

- And they will fill a daily checking recording spreadsheet on the wall.

Not all the workers will have to do this.

The key workers will have to do that in the morning and in the afternoon.

Next, I check the high bay light samples with the ESD control ring on my wrist.

Then, I come to the aging testing room, and see what they test and their reports.

- I can see many details regarding the test.

- For every product, they do an aging test for 6 hours.

- According to our understanding of the lighting industry, 6 hours of aging time is OK.

- Coincidently, I happen to see some lights as high as 1,800 Watt for the aging test.

After I double check, it can be sure that these products are really products of their own.

- This is very important, and can’t be overemphasized.

- If you just audit a supplier’ showroom, they may borrow some products from another manufacturer.

- And put those samples in their showroom and claim all as their products.

So, we have checked:

- AOK’s experience and products in their showroom.

- And also their production lines, and the aging testing room.

- We can find these products.

- That means they really focus on these products.

- They really have rich experience with these products.

This is very important.

Step 6. Visit the electronic material warehouse

Last, I visit the electronic material warehouse.

Right in front of the door, we can see some curtains here.

This is the anti-static curtain.

- So, when I go into the warehouse, my hand and my head touch it.

- The static on my body will transfer to the neutral cable.

After getting inside, I feel very comfortable.

Because now it’s August here in Shenzhen.

It’s very hot and highly humid, but here I feel dry and cool.

- Inside, we can see the air conditioner.

- This is a standard requirement for the electrical material warehouse.

- To ensure proper humidity and temperature for the warehouse, they have to use the air conditioner.

So, this is OK.

This is the standard.

Meanwhile, I can see some machines.

- There is a drying machine, which can reduce the humidity of the air.

- And there is a small meter on the wall for monitoring humidity and temperature.

- The warehouse keeper uses a spreadsheet for daily checking records.

- Hold the temperature and the humidity.

When we do the audit in the warehouse, besides the temperature, humidity, and ESD control, we also prefer to see which kind of raw materials we can find.

We can see Lumileds, which is a famous global brand, and many outdoor lights are using it.

Conclusion

That’s all for this quick manufacturer’s production audience.

I didn’t do a comprehensive audit this time because of some reasons.

- But it has included some important information about this factory’s quality management process.

So, what do you think about it?

Can it give you some confidence to work with this supplier?

- If you can give us any comments it would be very helpful.

- And encourage us to make more similar content.

At last, even a supplier verified by us doesn’t mean 0 risk.

If you want to get reliable quality from the supplier, you have to follow a very strict process.

Last but not least, we can help you with sample testing, factory audit, production audit, pre-shipment inspection, and during production inspection.