As a third-party quality inspection company, BackMorning has seen many quality issues.

Most of them can be sorted into 3 main categories.

- Applied techniques are not fit for production

- The product designs have issues of themselves

- There are communication issues

- Manufacturers are in a hurry for deliveries

We can say it’s rare to see quality issues due to inferior materials and shoddy workmanship.

This is because buyers and OEM/ODM manufacturers that work with us are reputable companies.

Their sizes are not small and have strong beliefs in business ethics.

However, some other manufacturers do make money by inferior materials and shoddy workmanship.

For example, we disassembled a portable power bank recently.

It has some 18650 lithium batteries inside.

This kind of batteries are also widely used with outdoor LED lights.

For this reason, we decide to talk little bit about this story.

Disassembling Steps:

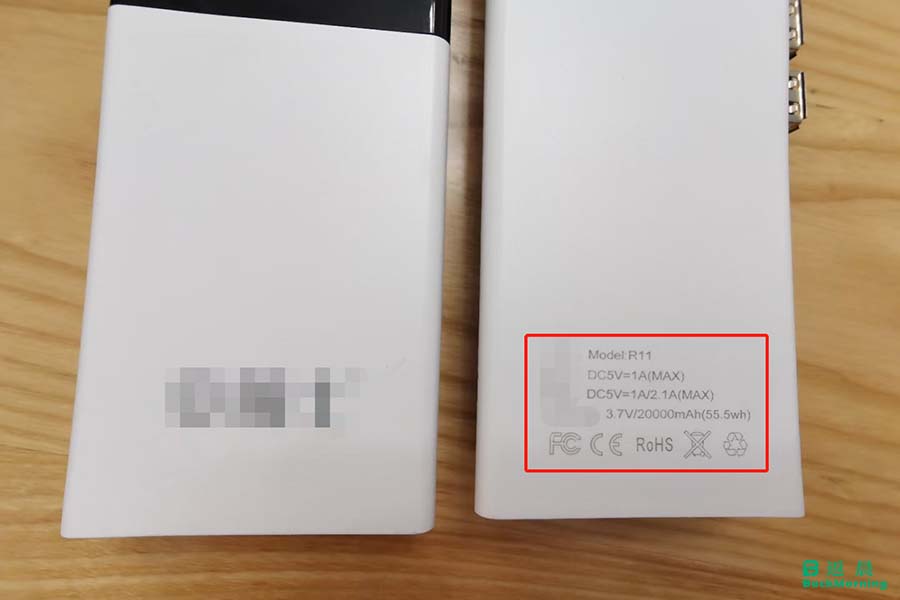

1. Impression on its exterior

It feels a bit heavy, but the power supply is not sufficient.

There are CE, RoHS, FCC marks on the cover.

This product looks like qualified at the first glance.

2. Opening the cover

There are 5 AA batteries inside.

However, 3 of them have different colors from the other 2 pieces.

That’s weird!

3. Careful examination

Surprisingly, those 3 batteries are not soldered with others.

That’s even weirder.

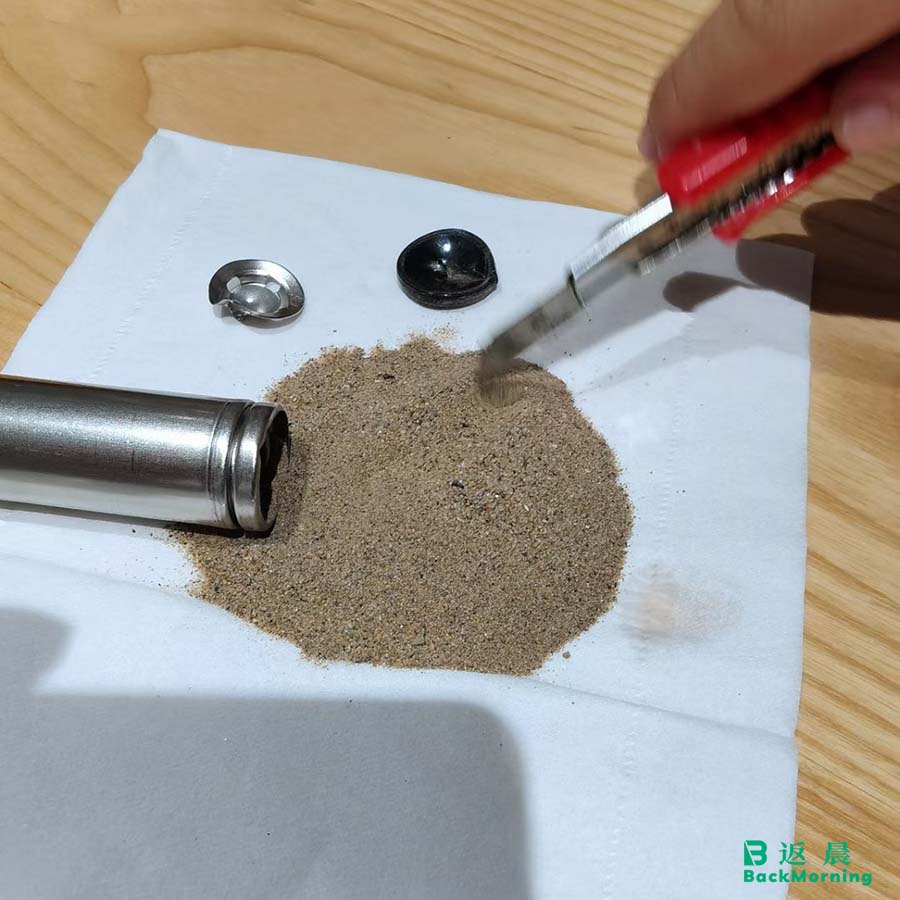

4. Uncovering the truth

We decide to open the cells of the 3 batteries at the risk of fire.

As a result, we see only sand inside them.

Unbelievable!

They give us a new lesson!

Later, we learn that this portable power bank is a gift for buying a mobile phone.

There is nothing more expensive than something free.

We wish to remind purchasers again.

To receive good quality products, there will be 2 conditions.

1). Purchasers should give reasonable prices to manufacturers.

2). Purchasers need to be able to do proper supplier quality management, which includes:

- Capable to do due diligence about manufacturers

- Capable to test samples provided by manufacturers

- Capable to do quality inspections for mass production

Generally speaking, you can communicate and negotiate prices with manufacturers by phone calls and emails.

However, quality management will be far more complicated.

- Quality inspectors will have to go to the factories for on-site inspection

- Quality inspectors will have to possess some fundamental knowledge, skills and experience

- Purchasers will have to invest in some professional instruments for quality inspections

What can you do?

Actually, you can consider working with a local third-party quality inspection company.

For example, BackMorning is such a company focusing the LED lighting industry.

And we’ve already been working with some global reputable lighting brands.

Our competitiveness is professional quality inspection services in the LED lighting industry.

They include 3 parts:

- Pre-shipment inspection

- Sample testing

- Factory production audit

If you still wish to know more about us, you can refer to these pages.

Feel free to drop us a line.

We reply to most emails in just a few hours.

Related posts:

UGR Test according to CIE 190:2010 for a French Customer

UGR Test according to CIE 190:2010 for a French Customer

Two Tips for Buying Good Quality LED Lights

Two Tips for Buying Good Quality LED Lights

9 Reasons Why the Quality of Products Made in China Isn’t Poor

9 Reasons Why the Quality of Products Made in China Isn’t Poor

7 Reasons to Consider Buying from Manufacturers in China

7 Reasons to Consider Buying from Manufacturers in China

Pre-shipment Quality Inspection for 1,500W LED Stadium Lights

Pre-shipment Quality Inspection for 1,500W LED Stadium Lights

13 Steps to Inspect LED High Bay Lights before Shipment

13 Steps to Inspect LED High Bay Lights before Shipment