There are several common LED lighting quality issues that can be found in the shipments sourced from China and Vietnam during the quality inspection. It’s important to note that not all the factories produce low-quality products, but some might cut corners to reduce costs. You should also know that some factory’s experience are not rich enough, this will increase the quality risk. Here are some common lighting quality issues to be aware of:

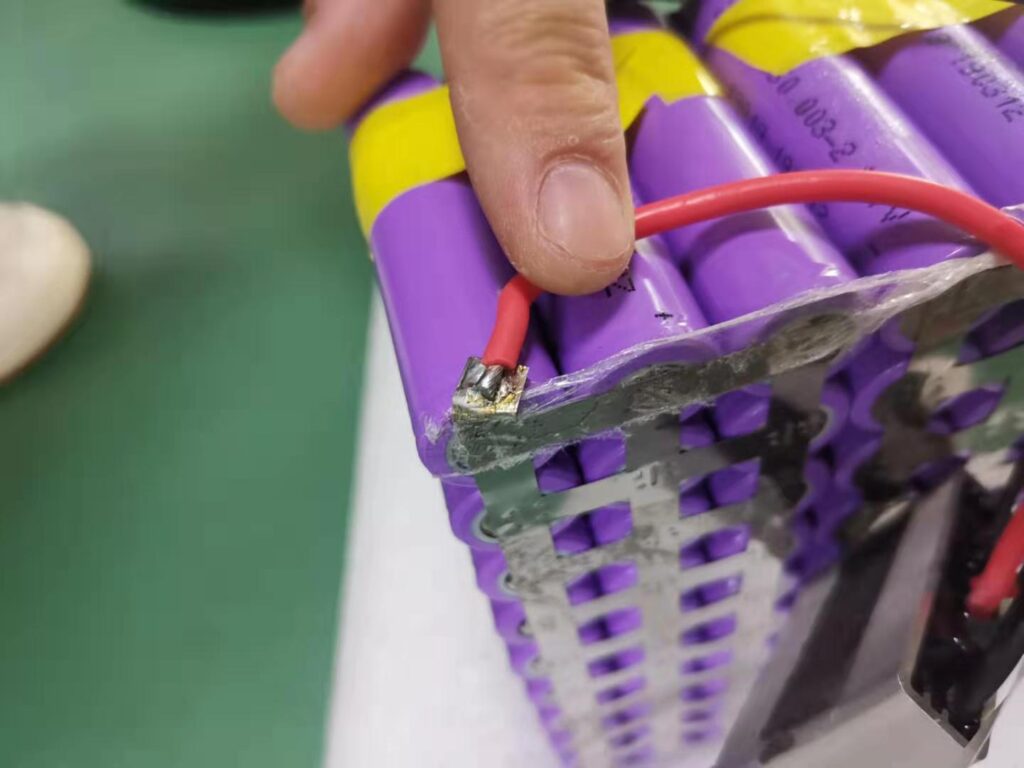

1.Poor soldering: Inadequate soldering of the LED components can lead to weak electrical connections, causing flickering or even complete failure of the LED lights. Poor soldering may result from using low-quality solder or insufficient soldering technique.(Below picture is the battery for a solar street light, the soldering quality is bad)

2.Inconsistent color temperature: Color temperature inconsistency can occur when different batches of LEDs have slightly different color temperatures, resulting in an uneven light output. This can be due to using LEDs from various suppliers or failing to maintain tight controls over the manufacturing process.(Below different color maybe caused by using wrong LED chips, or bad workmanship during the production.)

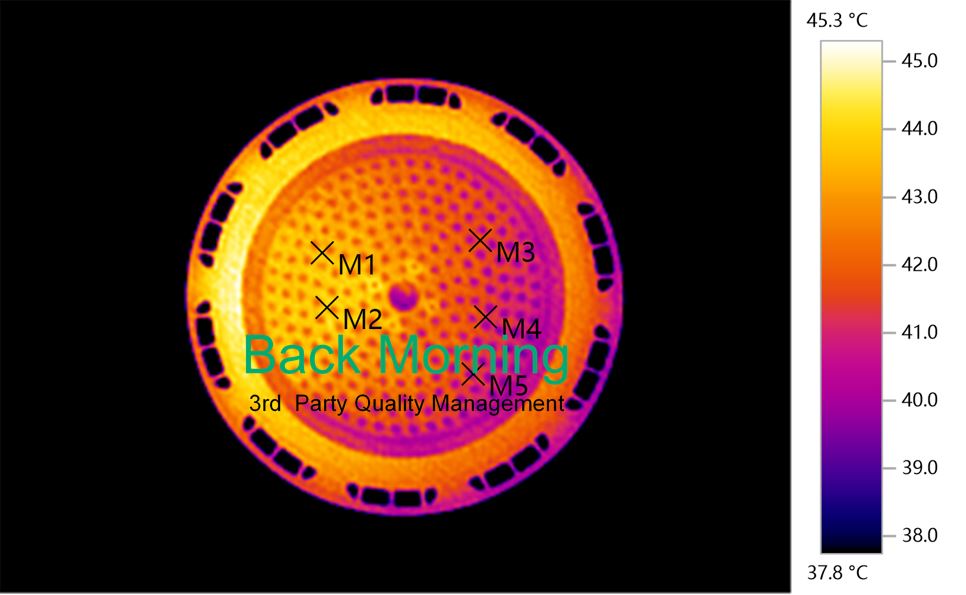

3.Substandard heat dissipation: Inadequate heat dissipation can lead to a shorter lifespan of the LED lights and reduced performance. Some manufacturers may use low-quality heat sinks, insufficient thermal paste, or poorly designed heat dissipation systems to cut costs.

Reminding: the below picture shows us some lighting quality issues are not caused by lacking of material, but by wrong manufacturing process include the casting process. You can see the heat transfer is not uniform or at normal in the below highbay light. Most of the Lighting Quality Issues are related to 5M1E.

4.Low-quality driver components: The driver is a crucial component of the lighting products, responsible for converting the input voltage to the appropriate current for the LEDs. Using low-quality driver components or improper design can lead to unstable performance, flickering, or premature failure of the LED light. 10 years ago around 2012, driver technology was not stable, it caused a lot of lighting quality issues. Now, the driver technology is becoming stable, but it’s still a big lighting quality problem maker.

5.Incorrect binning: Binning is the process of sorting LEDs based on their performance characteristics, such as luminous flux and color temperature. Poor binning practices can result in inconsistencies in the performance and quality of the final LED product. To avoid this kind of issue, you are suggested to test the spectrum of the LED chip samples, and test the complete lighting product too.

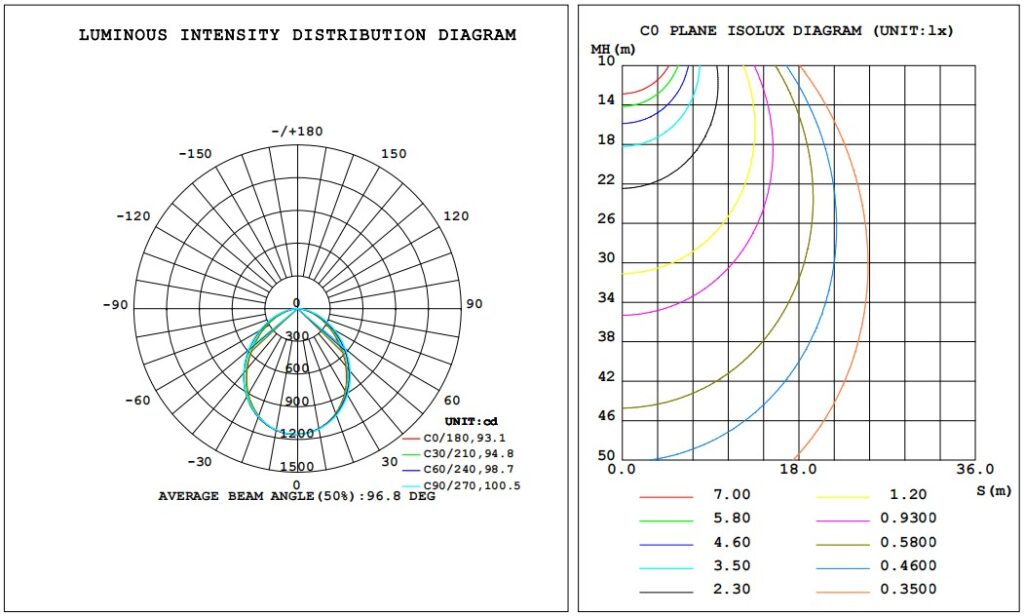

6.Inaccurate product specifications: Some manufacturers may overstate the performance specifications of their LED lights, such as luminous efficacy, Ra, CRI, R9, Beamangle, lifespan, IP rating, and power consumption. This can mislead buyers and result in customer dissatisfaction when the products do not perform as expected.

Reminding: if the customers\buyers don’t have the instruments or strict quality management process, this kind of lighting quality issues are not easy to be found, you are suggested to test the samples by 3rd party before release the order to the supplier, and do a pre-shipment inspection by yourself or 3rd party quality inspection company.

To mitigate these risks, it’s essential to partner with a reliable and professional third-party quality inspection company to ensure the LED lights meet the required quality standards and specifications.

We can help you in China to avoid 95% of above lighting quality issues, get high quality LED Lighting, Solar and Electric products, by providing you supply chain management service: Inspection, Testing, Introducing qualified manufacturers, Design, and New product development,etc.

Email:[email protected]

Wechat: LNY0539

Whatsapp: +86 18616827523

This is a part of our laboratory in Shenzhen: