Table of Contents

1. Check composition of LED Strip Lights

1.1 Check the pallet and Qty

Our inspector go to the factory warehouse, check the pallet and qty, according to the customer’s list

1.2 Check Carton information

Randomly select samples according to AQL standard and check its sticker info(PO number, Product name,etc.) on the carton

1.3 Check inside the carton

Open the carton and check inside packaging, accessories, quality certificate according to buyer’s requirements

2. Instrument testing

2.1 Check its electric data

Check Power, PF @ rating voltage

2.2 Pull testing

2.3 Check the dimension

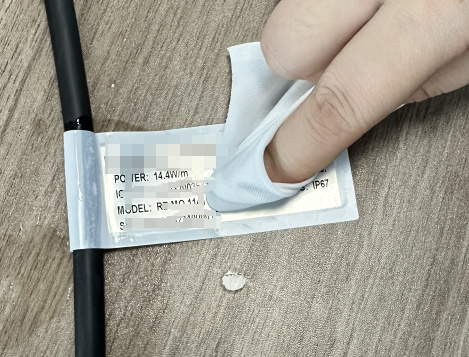

2.4 Check the label printing quality

Use petrol or ethyl alcohol

2.5 Aging test

Turn on the lights for >4 hours

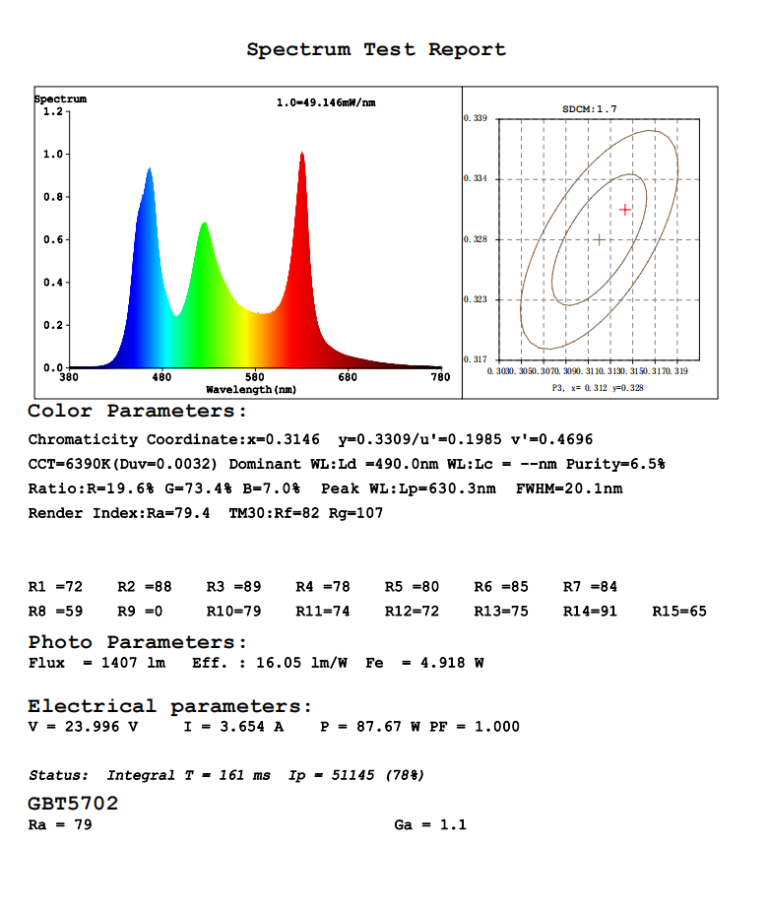

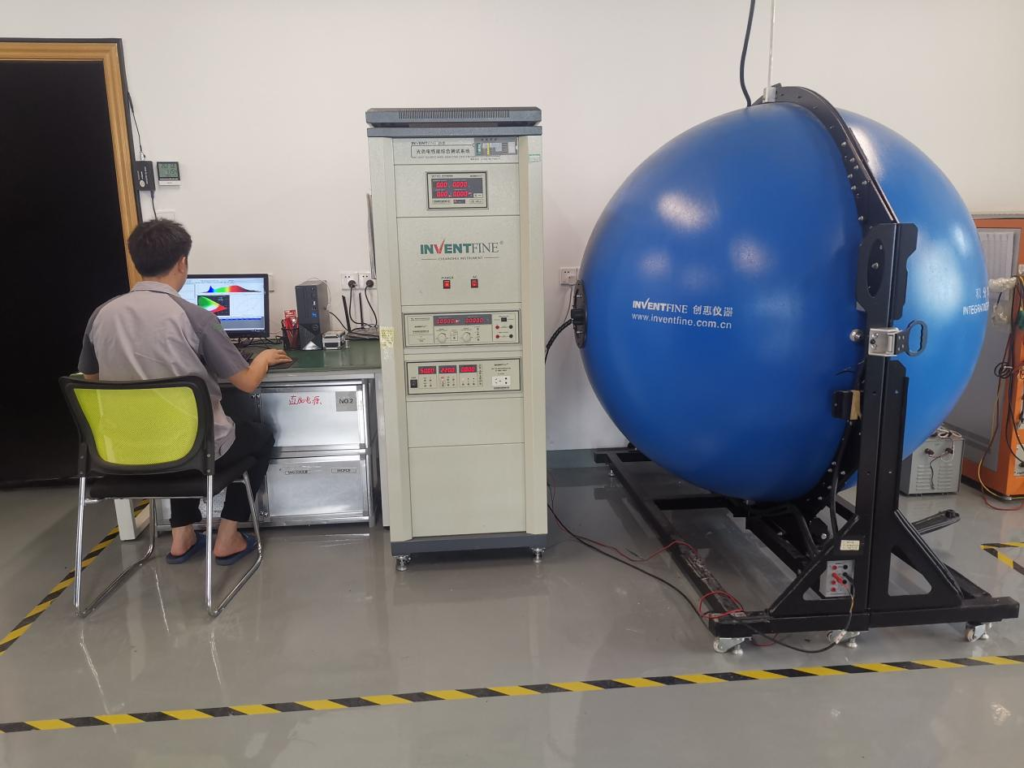

2.6 Spectrum testing

Check the Ra, Color Temperature, SDCM

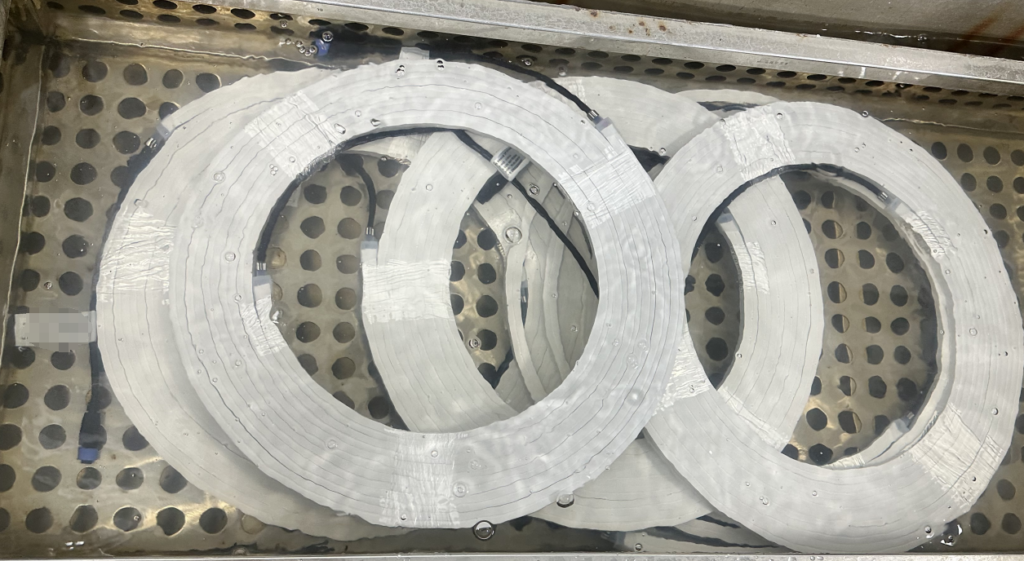

2.7 IP Testing

Test the lighting samples underwater, this is not a standard way, however it’s suitable for big qty testing in the factory before shipment.

After above 10 steps, we will prepare a quality inspection report, and send it to the buyer within 24~48 hours.

As a third-party quality inspection company, we are equipped to safeguard the quality of your LED Lighting products. Our services encompass professional quality inspections, sample testing, and assessments of factory capabilities to provide you with peace of mind regarding product excellence.

Email: [email protected]

WeChat: LNY0539

Whatsapp: +86 18616827523

Web: www.backmorning.com

Supply Chain Management Professor.

Quality Inspector in Lighting Field and Steel Structure Field.

Certified Welding Inspector by American Welding Society.

15 Years' experience of supplier quality management.

Six Sigma Green Belt.

Related posts:

10 Steps to Inspect LED Tube Battens before Shipment

10 Steps to Inspect LED Tube Battens before Shipment

14 Steps to Inspect LED Panel Lights before Shipment

14 Steps to Inspect LED Panel Lights before Shipment

12 Steps to Inspect LED Linear Lights before Shipment

12 Steps to Inspect LED Linear Lights before Shipment

11 Steps to Inspect LED Down Lights before Shipment

11 Steps to Inspect LED Down Lights before Shipment

13 Steps to Inspect LED High Bay Lights before Shipment

13 Steps to Inspect LED High Bay Lights before Shipment

Top 9 Quality Issues with LED Lights

Top 9 Quality Issues with LED Lights