Including Suggestions by BackMorning, a third-party quality inspector with leading global brands

LED lights are good for indoor and outdoor applications.

But that doesn’t mean they are perfect, and you can pick any brand as a user.

Or you can work with any manufacturer as a brand owner or retailer.

There are some quality issues that come with buying LED lights.

And these issues can mean big problems down the road if you don’t know how to spot them before making your purchase.

That’s why we’ve put together this list of 9 quality issues with LED lights.

These 9 most frequently seen issues are based on BackMorning’s experience.

We see them during sample tests, production audits, and pre-shipment inspections.

And some of those manufacturers are suppliers of some remarkable brands.

You should watch out for them when making your choice between different brands or models.

Take these notes below for reference.

No matter whether you are a regular user, or a brand owner, or a lighting solution provider.

There are many kinds of quality problems with LED lights.

This article will show you 9 LED lamp quality problems that we often encounter, briefly analyze the reasons for their occurrence and countermeasures.

1. Waterproof issue – Water in the lights

We can say it is the top of all quality problems with outdoor LED lights.

Because among all our tests, water leakage accounts for more than 40% of the total problem.

There are multiple reasons for LED lights to have water inside.

1). One important reason is incorrect installation and application.

Incorrect orientation of the installation

Improper wiring without using waterproof connectors

The application doesn’t match and the lights’ IP rating

2). Another important reason can be the lights themselves.

Specific causes can be the design of the lights.

And the assembling processes during production.

These lead to disqualified sealing performance against moisture, liquid water, etc.

For example, incorrect positions for the waterproof tapes.

Incorrect sequences for fastening screws

And aging waterproof materials, etc.

2. Harshness issue – Avoid harsh LED lights

There are 2 potential reasons for this issue.

The first reason can be:

The UGR value of the light (also known as the glare index) exceeds the requirements.

Pick the lights with UGR < 19 or UGR < 16 according to the conventional standards,

Unfortunately, some LED lights with excessively high UGR parameters.

So, they give you a blinding feeling after installation.

Suggestion:

Ask the manufacturer to provide a test report of UGR.

Make sure the test result is within the limits.

They can do it with a photometric distribution meter.

People also call it IES testing or Dark Room test.

If your supplier is not able to do that, find a quality inspecting company like BackMorning.

The 2nd reason can be:

The harshness of LED lights is also related to the installation method, density, and height.

The ones with good UGR are still likely to be harsh or not bright enough after installation.

Solution:

Better to simulate lighting effects before purchase or installation.

This is particularly important for lighting designers or lighting solution providers.

Remember to ask the manufacturer for IES files of their lights.

Let the designer simulate it with software (Dialux) for proper applications.

3. Color issue – LED lights look blue

If you notice this with a LED light, that means its color temperature is too high.

Some users may have noticed the color, but may not have realized it’s a quality issue.

Most regular users think the light is good as long as it’s bright enough.

But in fact, we need comfortable and healthy light.

Generally, we recommend:

Color temperature < 4000K for indoor applications, like homes and offices

Color temperature < 6000K or 5000K for outdoor applications

There are many lights with color temperatures that are too high.

Especially, the color of some cheap lights will turn blue after a while.

The cause is usually the LED lights themselves.

Their parts must have some potential quality issues.

Suggestion:

Replace the LED light with a high-quality brand.

Choose a light with a lower color temperature.

4. Insulation issue – Resistance of LED lights fails

Just like all electronic products, LED lights also have the risk of electrical leakage.

Therefore, governments across the world have laws and regulations that require LED lights must have a certain insulation capability.

Typical governmental standards are the UL in the US, the IEC in Europe, and the GB in China.

Normally, strict insulation tests are mandatory for LED lights before production and shipment.

However, it’s a common practice for manufacturers to test by picking random samples from production.

Unfortunately, this practice is not strict enough to guarantee the safety of all LED lights.

So, it can lead to some products that do not meet the safety standards.

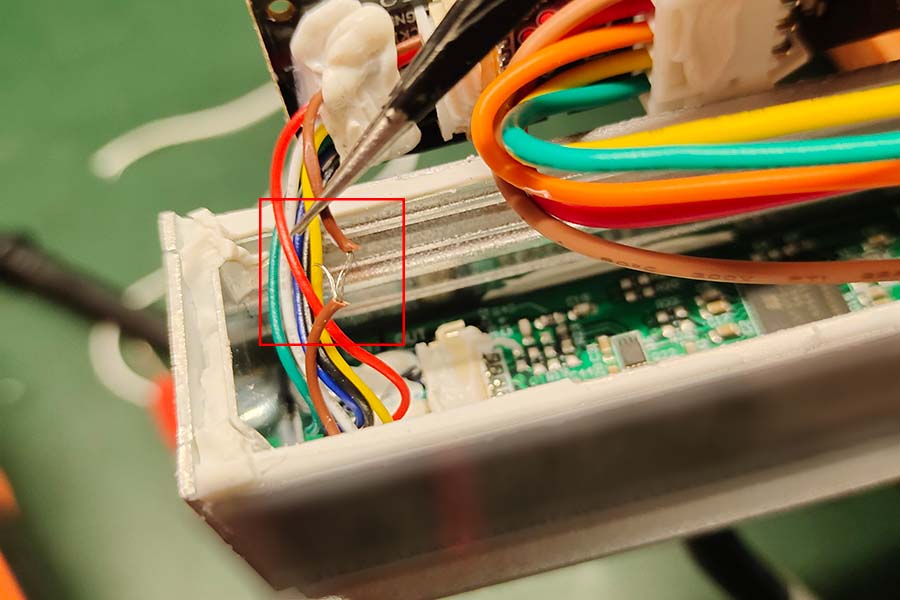

The pictures below are for a wall washer light that we find with substandard insulation.

The manufacturer presses one of the wires when assembling the fixture.

This mistake causes the rubber to break, so the housing of the light has electrical leakage.

5. Life span issue – The lights go out

From time to time, we can see that the ceiling lights at home no longer go on.

The downlights in the office are dark after a while.

The landscape lights in the garden do not light up anymore.

It’s not uncommon that some people think LED lights have a short life span.

Actually, this is a misunderstanding.

You may not know:

A qualified LED light can last more than 5 years, even 10 years.

There are 2 typical reasons for this life span issue.

One reason is the working environment has negative factors for the life span.

For example, voltage fluctuations, and high ambient temperatures.

The other reason is the LED lights have quality problems of themselves.

For example, LED lights are made with low-quality parts.

Production procedures have issues with quality management.

Workers on the production lines haven’t assembled the lights properly.

Suggestion:

Develop LED lighting products in accordance with APQP.

And manage the quality of LED lights effectively throughout the whole process.

At least, ask the manufacturer to provide test reports of the LED lights.

And ask the manufacturer to provide samples to do independent life verification tests.

6. Brightness issue – LED lights become darker and darker

It is a common question for LED light users:

Some LED lights are obviously darker after a few months.

Is this a quality issue, and can I ask for a refund or exchange?

Our answer is: Of course.

This is absolutely a quality issue.

And you deserve a refund from a reliable seller.

Unfortunately, some sellers may give you an answer like this:

The light is still working, and that means it’s still within its life span, regardless of its brightness.

Therefore, it is not a qualified reason for a refund.

But in fact, the definition for a LED light’s life span is clear:

When the total brightness (luminous flux) of a LED light goes down to less than 70% of its initial brightness (luminous flux) (L70), the light has come to the end of its life span.

Solution:

When you buy LED lights, ask the manufacturer to provide L70/L80/L90 reports.

Or life span test reports.

To be more reliable, ask them for samples to do tests yourself.

Particularly if you are a brand owner, or you are a lighting solution provider.

Better to make sure the lights you buy can last 5 years or even 10 years.

7. Illumination issue – Insufficient within the irradiated area

There are 2 major reasons for this issue.

1). The total brightness of LED lights is enough.

But the distribution of light has problems.

It is like hanging a light bulb on the ceiling.

It’s bright, and a lot of light is projected to the ceiling above if you don’t add a reflector.

Then some light is wasted.

2). The total brightness of the light is too low.

Or the luminous flux efficiency is too low.

In this case, even if the luminous angle is appropriate, the light still can’t reach the corresponding illumination requirements.

Suggestion:

1). Similar to point 1 above, ask the manufacturer to provide the IES file.

Let the designer simulate to verify whether the light is good.

Don’t use the light if it doesn’t meet the basic requirements.

2). Ask the manufacturer to provide the luminous flux test report for the LED light

It usually contains the spectrum report or photometric distribution test report.

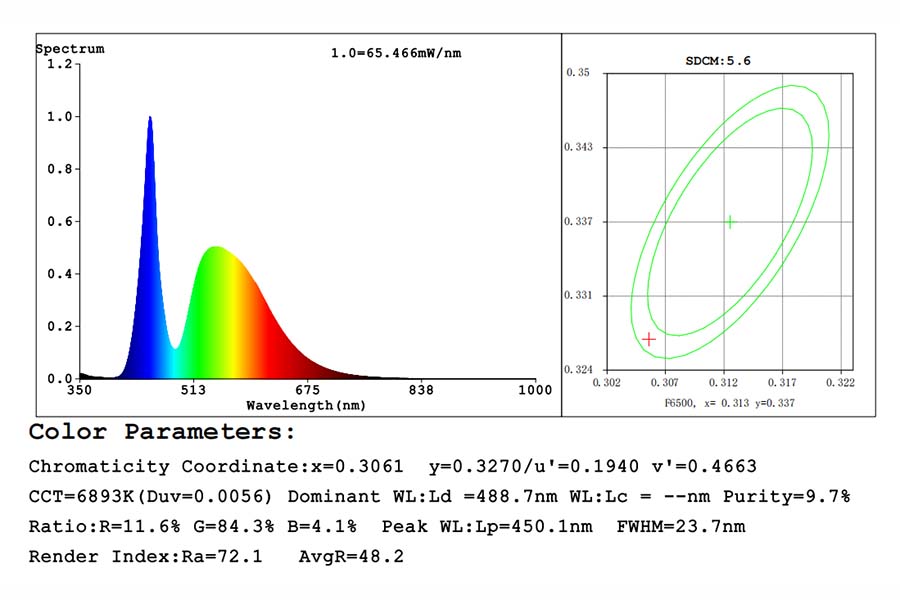

8. Consistency issue – Colors look different

This used to be a headache for many manufacturers.

Especially, this is very noticeable for LED downlights.

Usually, users install multiple downlights together.

If there are color differences among them, it is easy to recognize.

Unquestionably, this is not good for the user experience.

Fortunately, LED packaging technologies are more reliable in the last 2 years.

So, this problem has been less often seen.

However, that doesn’t mean it no longer exists.

You still need to check to make sure your lights don’t have this issue.

Here we wish to explain in some more detail.

This issue happens because of disqualified SDCM (Standard Deviation Colour Matching).

Meanwhile, some people take it for granted that Color Temperature and Color are the same.

And neglect the influence of SDCM, Ra, R9, and X,Y on the color of light.

Suggestion:

a. Strictly control SDCM, and require the manufacturer to do spectrum test for each production

b. Pick samples randomly for SDCM tests during the third-party inspection before each shipment

c. Use LED lights from the same batch for installation projects to minimize color differences

9. Shade issue – Becomes dark or yellowish

This issue is particularly bad for indoor applications.

Because it makes the room look darker.

Moreover, everything inside the room will thus look lower grade.

This phenomenon is particularly obvious with LED panel lights.

Suggestion:

Better not to choose low-cost but cheap LED lights.

Better to buy high-quality ones.

Their prices are more expensive, but you can be worry-free in 5 years.

Additional issues – Less frequently seen but do exist

In addition to the 9 most frequent problems mentioned above, BackMorning has also seen the following problems:

Not dimmable, though they should be (the lights strobe or make noise when dimming)

Flicker after the lights are turned on

Mosquitoes and dust are found inside the lights

Some LEDs no longer light up after a while, resulting in shadows

Strip lights don’t have sufficient adhesiveness

Lights with LoT function, but lose connection and can’t build a network

Lights with batteries but the working time is shorten too quickly

These quality problems are not so common.

So we prefer not to explain all of them in detail.

Last but not least, we’ve listed the most frequently seen quality issues with LED lights.

Keep them in mind and make sure to pick the ones with good quality.

If you are not sure about the quality of the LED lights you purchase from your manufacturer, contact BackMorning.

We have a Free Test Program valid for LED light buyers of all types.

You can verify at no cost.

Related posts:

UGR Test according to CIE 190:2010 for a French Customer

UGR Test according to CIE 190:2010 for a French Customer

Two Tips for Buying Good Quality LED Lights

Two Tips for Buying Good Quality LED Lights

Comparing LED Streetlights with Different IK Ratings

Comparing LED Streetlights with Different IK Ratings

12 Steps to Inspect LED Linear Lights before Shipment

12 Steps to Inspect LED Linear Lights before Shipment

11 Steps to Inspect LED Down Lights before Shipment

11 Steps to Inspect LED Down Lights before Shipment

10 Steps to Inspect LED Strip Lights before Shipment

10 Steps to Inspect LED Strip Lights before Shipment