You may have heard the term “Made in China” and automatically assumed it meant low quality.

However, that is not always the case.

- The quality of products made in China is related to various factors.

- The quality of products made in China can vary from one manufacturer to another.

There are different types of products made in China.

- Some have high-quality materials or processes but still end up being low-quality overall.

- Some have both high-quality materials/processes and high-quality overall results.

More importantly, quality comes from process management.

This includes how you screen and select the right manufacturers.

And, also include how you manage the quality of your supplier.

- Factory audits, sample testing, and pre-shipment inspections, etc.

If properly managed, a small manufacturer can offer products of quality the same as those big brands.

If not properly managed, a big manufacturer can result in quality even lower than a small manufacturer.

- Actually, your capabilities for screening, selecting, and managing suppliers play an important role in the quality of products.

Probably you may need to learn more before completely understanding the points.

Below is a list of 9 reasons why the quality of products made in China is not poor.

And you can surely find good quality products and manufacturers.

- Many big brands have their factories or manufacturers in China after all.

1. Key figure indication

It’s always good to use numbers to do basic analysis.

Multinationals must have excellent professionals to choose the right manufacturers.

Following their strategy is something that you can consider.

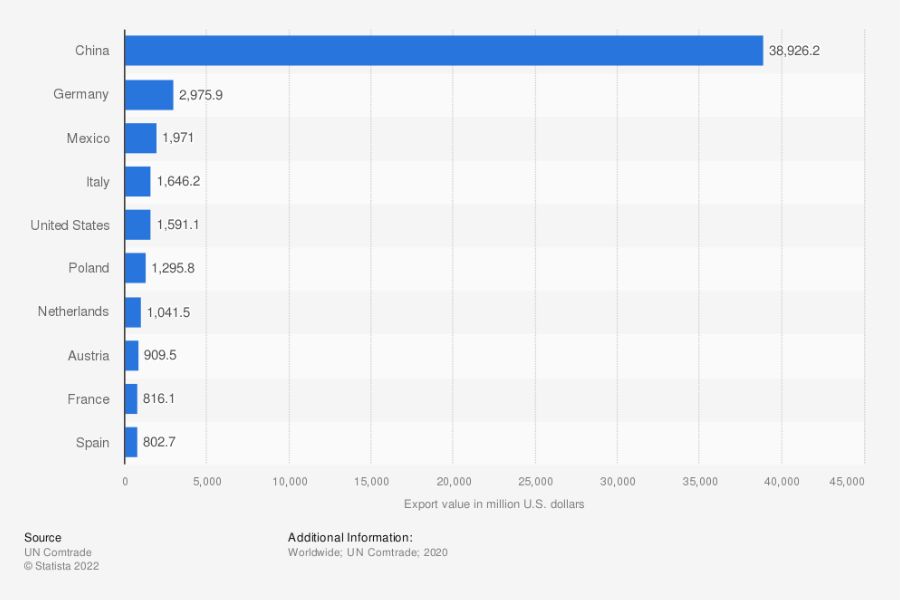

Look at a critical number regarding market shares of major exporters in the LED lighting industry.

- Leading exporting countries of lighting fixtures and fittings worldwide in 2020 (in million U.S. dollars, by Statista).

- The LED lighting manufacturers make China an overwhelming leader in this industry.

Did you know that some of the top 10 global lighting brands have some of their manufacturers in China?

- These brands include some the household names like Philips, Osram and GE.

2. Manufacturers gain experience

It is the same as with anything else in the world.

Getting product quality to where it is now in China has been a long road.

This story is quite the same as those of Western countries.

No one produces products of good quality since the beginning.

It always takes time to learn and gain experience.

And it also takes time to optimize manufacturing techniques and processes.

This is the same for manufacturers in China.

Many manufacturing industries didn’t exist about 20 years ago.

It took some time for the manufacturers to learn the right things and the right ways.

There is a big difference between now and then regarding this aspect.

Many manufacturers already have more than 10 years or even 20 years in one industry.

And there is even a generation of manufacturers who can design and innovate.

No longer limited to only OEM manufacturing or copy and counterfeit.

3. Automatic technologies widely applied in manufacturing

The majority of manufacturers used to produce products with mostly manual workers.

However, automatic devices, machines, and production lines are already widely used in factories.

This change can help manufacturers eliminate many human errors.

Especially, there are automated inspection machines.

Technically, it makes it possible to inspect every single product on the production lines.

This was not possible with manual workers in the past.

In return, the quality of products improves, and so has customer satisfaction.

4. Quality management systems and certifications widely adopted

The optimization of quality management is like manufacturing techniques and processes.

It takes time for manufacturers to learn and gain experience about how to manage quality properly.

Training, consultancy, and service providers of quality management were rare before.

Even some professionals who studied this subject didn’t have applied experience.

Most people used to manage quality based on their assumptions.

Rather than verified scientific theories or best practices.

But now many manufacturers have a department of quality professionals.

And there are many reliable third-party quality management service providers.

This is also an important step in improving product quality made in China.

5. Markets are more and more competitive

Probably you may not know that the market in China used to be manufacturer dominated.

They were not many manufacturers to fulfill the supplies for market demands.

Theoretically, manufacturers could sell whatever they could produce.

Not long after China joined the WTO, the demand for manufacturers increased dramatically.

Quality was not so important in such a market at that time.

However, now the time has changed.

Generally speaking, the market has been dominated by buyers.

In almost every manufacturing industry or for every product, there are plenty of manufacturers.

This has forced manufacturers to place emphasis on product quality.

6. Investment in new technologies

The manufacturing industry in China has evolved over time.

It began by making regular consumer products.

But many manufacturers also enter industries that are new technologies.

Chinese manufacturers can even play a leading role in industries that begin from the same start line.

The lighting industry is one of these examples.

- Many of the top global lighting brands have factories or manufacturers in China.

- And lighting fixtures and fittings exported from China are far more than other countries.

7. Poor quality often originates from improper supplier selection

It is understandable that buyers want the product quality to be as high as possible.

But simultaneously push the manufacturer for prices as low as possible.

- Don’t forget “You get what you pay for”.

There is always a cost behind everything.

- Make sure you evaluate costs properly and avoid pushing too hard for every cost.

Otherwise, it’s very likely the quality won’t be good.

In certain aspects, reducing prices is almost the same as reducing the quality of the finished product.

When you request lower prices for your products, don’t forget to evaluate costs properly.

Good quality always requires materials and manufacturing techniques and processes of certain degrees.

8. Communicating effectively

Most manufacturers in China will make things exactly to your specifications.

Some quality issues actually come from the communication between buyers and manufacturers.

Particularly, when you don’t take the time to properly specify every detail of the products.

- “Quality begins with the buy.”

This is a commonly believed saying in the quality industry.

The buyers should provide detailed bills of materials (BOM) and specification sheets.

Letting manufacturers know your expectations is key to getting the results you want.

9. Even smart people can do dumb things

To be fair, many quality problems are not deliberate results by the manufacturers or buyers.

People make mistakes, and this is inevitable.

- The chances of quality issues are bigger if you completely rely on your manufacturer for quality management.

Some quality problems are avoidable if there is someone else who keeps an eye on the products.

You should consider working with a third-party inspection company.

Third-party inspection companies are worthy, compared with the total cost due to lower quality.

Conclusion

We’ve explained 9 of the most important reasons why the quality of products made in China is not poor.

Some of them are avoidable if you take the DIY approach for DIY quality inspection.

However, some of them are more challenging and require training, skills and experience.

Hope they can help you better manage the quality of products you buy from China.

In case you need a partner, you can consider BackMorning.

Especially, we focus on the LED lighting industry.

You can send us an email and we usually reply in a few hours.

Thanks for reading!

Related posts:

Top 9 Quality Issues with LED Lights

Top 9 Quality Issues with LED Lights

9 Reasons to Work with Quality Inspection Company Focusing on LED Lighting

9 Reasons to Work with Quality Inspection Company Focusing on LED Lighting

Expected Characteristics for Quality Inspection Companies in China

Expected Characteristics for Quality Inspection Companies in China

7 Reasons to Consider Buying from Manufacturers in China

7 Reasons to Consider Buying from Manufacturers in China

12 Simple Questions for Screening Manufacturers Effectively

12 Simple Questions for Screening Manufacturers Effectively

Misunderstanding When Sourcing Backlite Panel Lights

Misunderstanding When Sourcing Backlite Panel Lights