Determining the quality of LED lights seems to be simple.

But this is not true for a quality inspector focusing on LED lights.

For regular users, a LED light is good as long as it comes on after you give them electricity.

Actually, this is far away from a fair conclusion.

There are various parameters that define the quality of a LED light.

Such parameters include spectrum data, light distribution data, safety, IP rating, etc.

Meanwhile, it requires certain technical skills and experience to inspect LED lights.

Particularly, there can be unexpected issues with proper testing conditions.

The quality inspectors must know how to deal with such cases properly.

Therefore, BackMorning recommends working with quality inspectors who focus on the LED lighting industry.

And we will list all the points that make sense one by one.

1. Understand various inspections of LED lights

Their quality inspection is fast and efficient.

They can test more samples and do more test programs.

For example, each man day of BackMorning can fulfill these inspection tasks:

- 8 Models of indoor lights

- 4 – 6 Models of outdoor waterproof lights

- All the important parameters will be checked

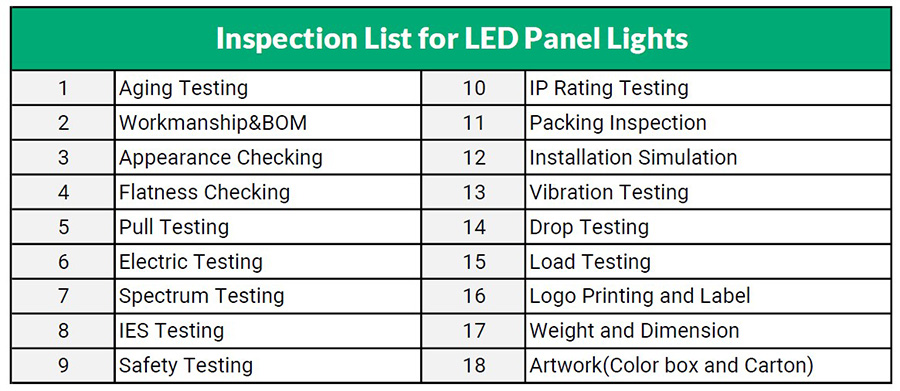

The following table is an example that shows the inspection tasks.

They are what BackMorning inspectors inspect for 600mm*600mm bottom-emitting panel lights.

2. Help you with continuous optimization

Professional LED light inspectors understand those technical parameters.

And also know the production management process of LED lights.

They can work with the manufacturer to optimize raw material management, static electricity protection, assembly and other processes.

A quality inspector – who doesn’t focus on LED lighting industry – is unable to do that.

This is very important for the long-term quality of your LED lights.

- Quality comes from the processes.

- Not only from the final inspection.

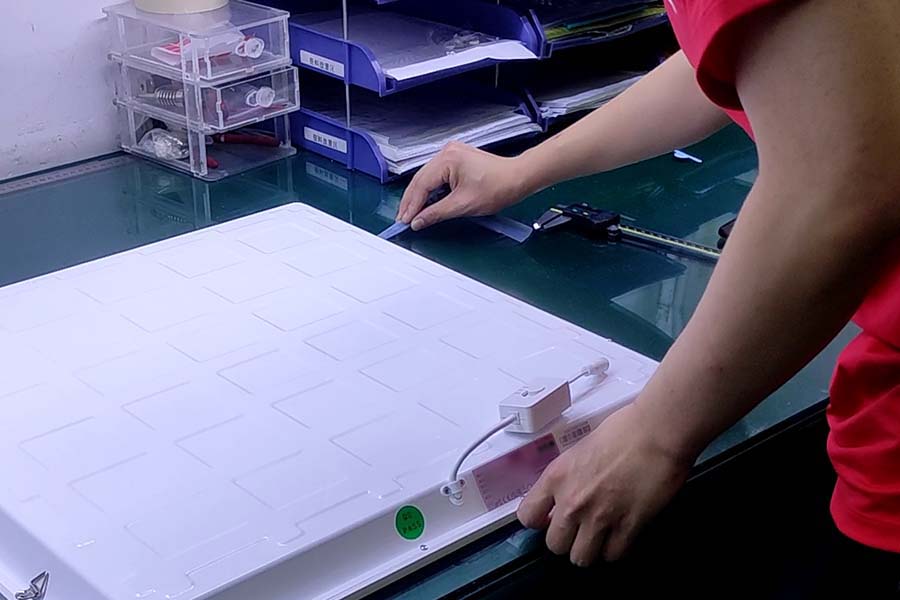

Image below:

BackMorning found that an LED light factory used the wrong ESD control method.

3. Push manufacturers for better quality during production

When a manufacturer knows that the inspection will be fulfilled by a professional LED light inspector, they will take it seriously.

For example, they will pay more attention to quality management during production.

This is very important for the long-term quality of LED lights.

Again, quality comes from the processes, not only from the final inspection.

4. Perform more reasonable inspection practices

Usually, a quality inspector can do his job according to the product’s specifications provided by the customer.

But for LED lights, there can be some limiting factors for proper inspection.

- It may be limited by time and the manufacturer’s equipment

- And also limited by insufficient data on the LED light’s specification

The inspector needs to ignore some unnecessary tests.

And, add extra tests that are not indicated in the specification.

5. Read test data fast and draw accurate conclusions

There are more than 20 parameters on a pre-shipment report for a LED light.

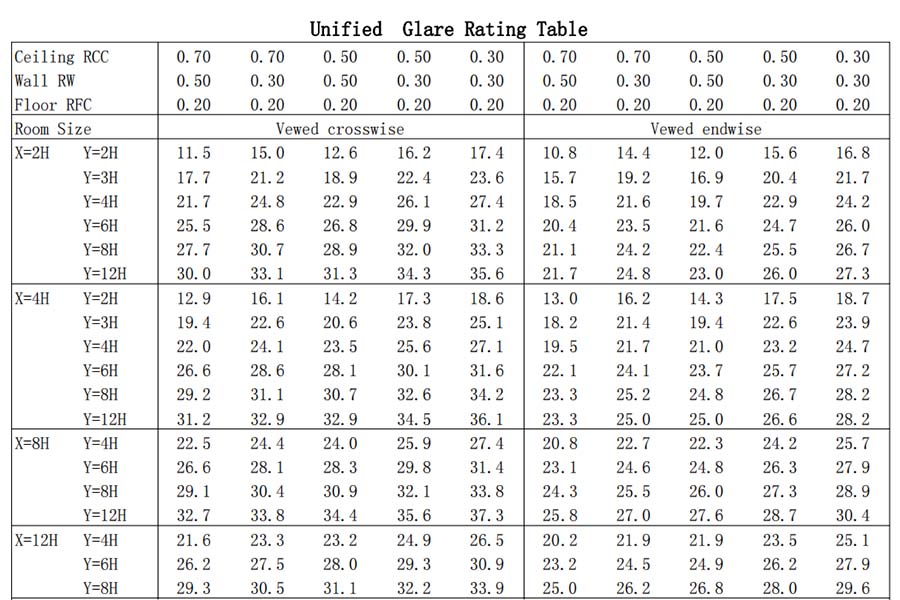

For example, the UGR value of indoor lights is very important.

Generally speaking, we will get a UGR table through the light distribution test.

But the UGR table has a lot of values, which one should prevail?

This is difficult for quality inspectors who don’t have sufficient knowledge about LED lights.

But not for professional LED light inspectors, this won’t be a problem at all.

6. Flexible in dealing with unexpected technical issues

There can be unexpected situations during tests and inspection tasks.

The ability to think out of the box is important.

- Professional LED light inspectors can be “flexible and professional to handle such issues”.

- This is very important for helping buyers beyond quality management.

For example, suppose the inspector is testing IP65 outdoor lights.

Unfortunately, the factory’s waterproof test equipment has issues with spraying water.

- What should we do?

- Should we ignore this test?

- Or take other alternative inspection methods?

Similarly, it takes time to do the light distribution test.

The manufacturer complains that this test is very troublesome.

- Should we take another alternative test?

These unexpected issues are difficult for quality inspectors outside the LED industry.

But they are not difficult for professional LED light inspectors.

7. Will not make mistakes in the vital details.

Such details include:

- Parameter settings for safety tests

- Preheating for spectrum tests

- Preheating for waterproof testing, water pressure, direction, etc.

8. Minimize damages to LED lights

Some inspection practices are destructive.

Professional LED light inspectors can reasonably arrange procedures.

We will try our best to avoid using these testing methods.

Or do such a test in the last step.

And communicate clearly with the customer in advance.

9. There is a team of professionals behind

A professional LED light inspector has a team behind him.

There are always some difficult problems that are not easy to understand.

Even the manufacturer may not know the right answer.

But a colleague who has more experience may have a better solution.

This is usually because he has already dealt with similar cases with other manufacturers.

Last but not least, if you happen to purchase LED lights from China, make sure to work with some professional LED light inspectors.

Consider BackMorning, in case you haven’t had a reliable quality partner yet.

We are a third-party quality inspection company focusing on the LED lighting industry since the beginning.

And proudly, we’ve been working with some of the top 10 brands with pre-shipment inspection and factory production audit services.

Our quality inspectors are all well trained.

And all are certified by top-notch brands.

Just drop us a line.

We offer discounts for new customers!

Related posts:

Quality Management Systems and Certifications Don’t Always Guarantee Defectless Products

Quality Management Systems and Certifications Don’t Always Guarantee Defectless Products

7 Things that Quality Inspection Reports Can’t Tell

7 Things that Quality Inspection Reports Can’t Tell

Comparing LED Streetlights with Different IK Ratings

Comparing LED Streetlights with Different IK Ratings

10 Steps to Inspect LED Tube Battens before Shipment

10 Steps to Inspect LED Tube Battens before Shipment

14 Steps to Inspect LED Panel Lights before Shipment

14 Steps to Inspect LED Panel Lights before Shipment

12 Steps to Inspect LED Linear Lights before Shipment

12 Steps to Inspect LED Linear Lights before Shipment