You might think that when you buy LED lights from a major brand, you have little to worry about.

After all, big brands should know what they’re doing, right?

For most regular users of products, big brands may equal quality.

1. Essential but not perfect

And for some professional purchasers, quality management systems and certifications can be synonyms for “quality guarantee”.

So, it will be hassle free to purchase from certified manufacturers, true?

Unquestionably, they are essential and can be helpful in some areas.

However, quality is more complex than just trusting a brand name, system, or certification.

Then how to find a manufacturer that offers good quality consistently for LED lights?

Usually, a quality management system or certifications will be a necessary part to consider.

And going to check on site will also be an important step for their factory audit.

- Unfortunately, not many people dive deep into those quality management systems and certifications.

- Or compare the difference between quality management theories and realities.

- Otherwise, you will realize there are some common misunderstandings about how quality is achieved.

As a third-party quality inspection company, we can say quality management systems and certifications don’t always work perfectly.

2. A real story with a big brand’ sample

Let us give you an example.

Recently we got an LED spotlight from the market.

It belongs to a very famous brand.

The plan is to use this sample for a spectrum test to explain some quality subjects.

We put the sample into our integrating sphere for the spectrum test.

1). General information about the sample

- Product: LED spotlight

- Basic parameters: 4.5W, 380 Lumens, 2,700 K

We collect the data at 2 times respectively.

- One is when the light goes on for 1 minute.

- And the other is after 30 minutes.

In this way, the data will be more reliable.

There is a technical reason behind this procedure.

The performance of electronic products may go down to a certain extent as time goes by.

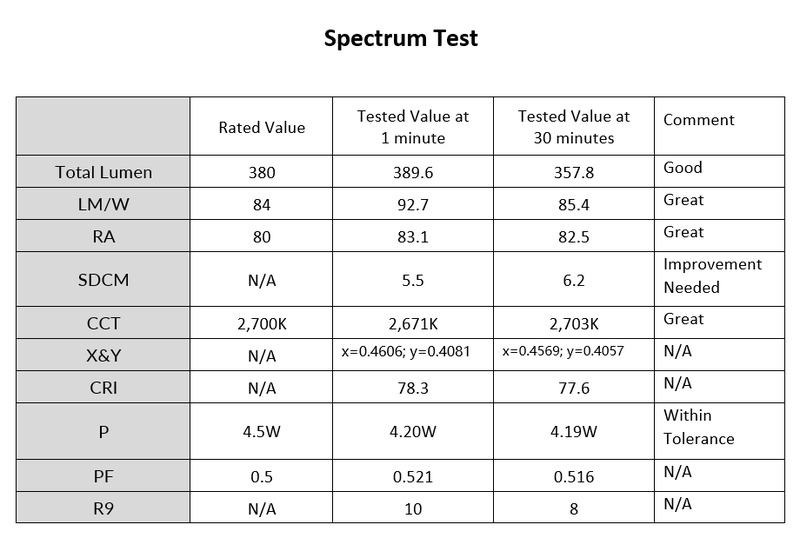

The table below lists some critical data that we got.

2). Spectrum test results

The results turn out this sample offer great actual performance, compared to its rated values.

For the LM/W, Ra, and CCT, those values are great.

They are the same or above the tolerance of the rated values on the sample package.

However, it has some parameters that need improvement.

This conclusion is based on our understanding of the common practices in the LED lighting industry.

3). Two major parameters to improve

The tested SDCM value is beyond a commonly accepted maximum value of 6.

This parameter is important, especially if the user installs multiple spotlights on the same ceiling.

If this parameter is within the tolerance, spotlights look quite the same when they are turned on.

If this parameter is too big, spotlights may have a noticeable difference when multiple are installed together.

Meanwhile, usually, the leading brands offer a bigger actual value for their Lumen (Total Lumen).

The tested value is below the rated value but still within the tolerance of -10%.

We can’t say this is bad, but not a common practice for big brands.

So, what do you think of the test results?

Maybe the result is a little bit surprising for you.

But not for us.

3. Not surprising for us

BackMorning is a third-party quality inspection company focusing on the LED lighting industry.

We’ve tested numerous LED lights and inspected hundreds of shipments.

The results are not so surprising for us.

- We already know that even smart people can do dumb things.

- It is the same for quality management.

The brands have quality management teams full of experienced professionals.

And their manufacturers have fundamental instruments for testing the products.

But why do this still happen?

4. Think of computer operating systems

A quality management system is a framework.

It can be applied to a very wide range of businesses.

Think of computers with Windows operating systems.

You can install a very wide range of software on it.

- Quality management systems and certifications indicate the manufacturer has managed procedures towards product quality.

- However, it doesn’t mean those procedures work perfectly to deliver products without defects.

Thinks of computers with Windows operating systems again.

Many users have Microsoft Office on their computers.

- But does it directly equal that the users can make beautifully designed documents?

- And their documents won’t have typos or grammar mistakes?

- Therefore, you still need someone else to check the documents before printing them out.

As for the manufacturing industry, “someone else” usually means third-party quality inspection companies.

5. Examples of possible causes

Below are a few points which will help you to understand why.

A manufacturer with certified quality management system doesn’t guarantee you a product without any quality issue.

1). Not main product line

One possible reason can be what you buy from a manufacturer is not their main product line.

Usually, a manufacturer can have more than one product line.

They spend most of their efforts and resources on the main product lines.

And those main product lines will have comparatively better quality in the long run.

For those that are not their main product lines, their efforts and resources may not be comparable.

2). New product development

Another possible reason can be what you buy from a manufacturer is still comparatively new for them.

That doesn’t mean that this product is completely new for this manufacturer.

That can mean that they need to add new features, add new functions or even redesign an old product.

At the early stage, some procedures still need improvement to be perfect.

3). Rushing for deliveries

It is common for manufacturers to rush for some deliveries.

Especially before the national holidays or festivals.

The workers and shipping companies have deadlines for deliveries.

The manufacturers can’t slow down a little bit to double check product quality.

Some errors may be less noticeable than normal working days.

4). Communication between buyers and manufacturers

This is also a possible reason for quality issues to happen.

It’s not uncommon for buyers to modify some product requirements after placing orders.

The salespeople receive the notifications from the buyers.

The notifications may need to pass a couple of layers to reach the workers on the front line.

They may make mistakes if the information is not transferred properly.

5). Unexpected weather changes

This may sound a little bit ridiculous at the first glance.

However, this is a technically honest cause for quality issues.

One example is the humidity in the air.

When it suddenly becomes very wet, it’s very negative for materials and components.

It’s not possible to build a completely sealed working environment.

But offer comparatively better managed working environments for most important procedures.

Therefore, there are still potential quality issues.

The reasons listed above are some of the possible causes for quality issues.

They are still possible to happen to your products even your manufacturers have certified quality management systems.

- You can never receive 0 defective products from any manufacturers.

- You can only minimize the possibilities of defective products to a certain extent.

Just like the example of making documents.

It is still possible for them to have errors.

That’s why you still need a third-party quality inspection company for better quality management.

You can consider BackMorning for third-party quality inspection.

We focus on the LED lighting industry since the beginning.

Related posts:

Top 9 Quality Issues with LED Lights

Top 9 Quality Issues with LED Lights

9 Reasons to Work with Quality Inspection Company Focusing on LED Lighting

9 Reasons to Work with Quality Inspection Company Focusing on LED Lighting

Expected Characteristics for Quality Inspection Companies in China

Expected Characteristics for Quality Inspection Companies in China

7 Reasons to Consider Buying from Manufacturers in China

7 Reasons to Consider Buying from Manufacturers in China

12 Simple Questions for Screening Manufacturers Effectively

12 Simple Questions for Screening Manufacturers Effectively

Misunderstanding When Sourcing Backlite Panel Lights

Misunderstanding When Sourcing Backlite Panel Lights